Technical Description:

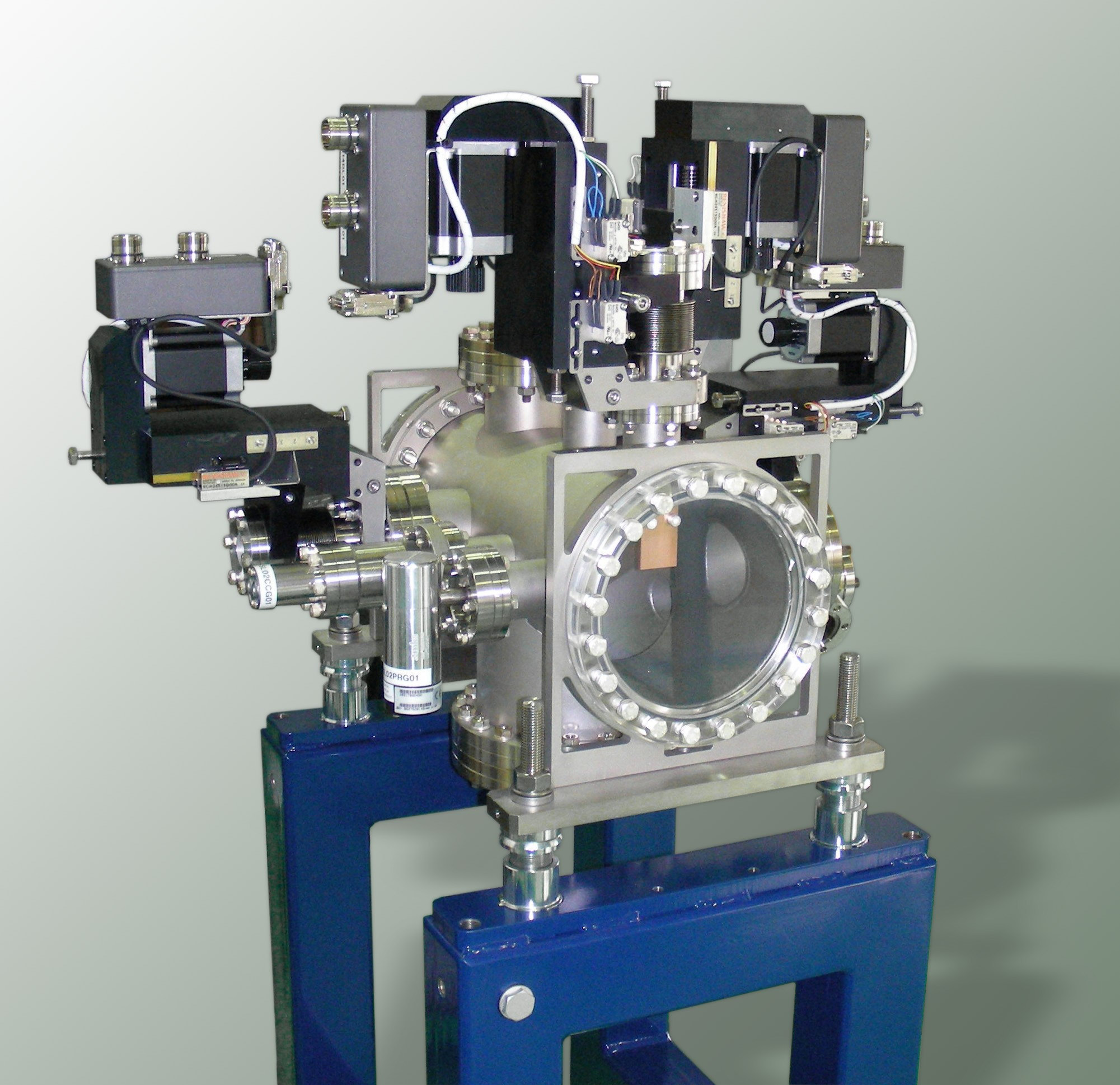

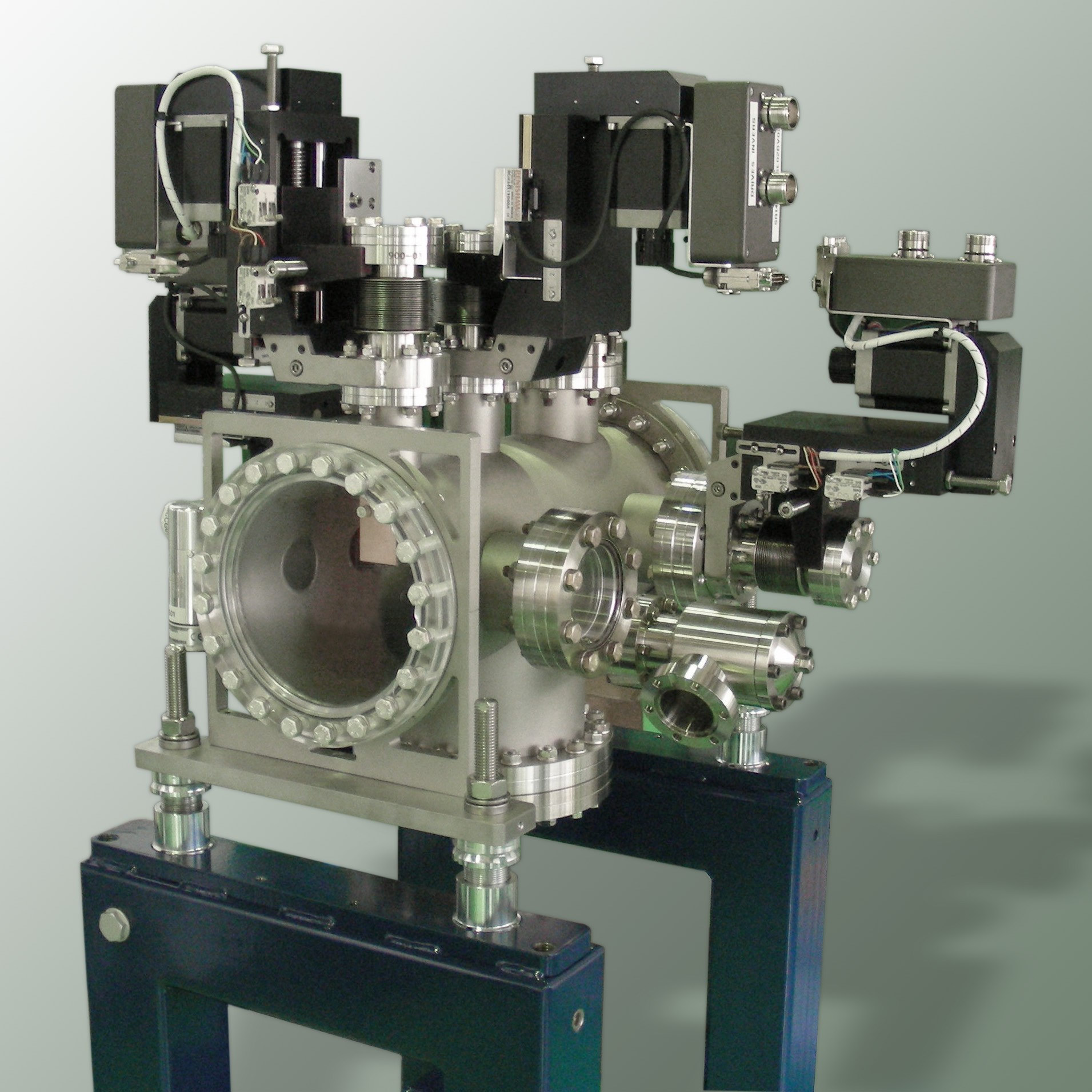

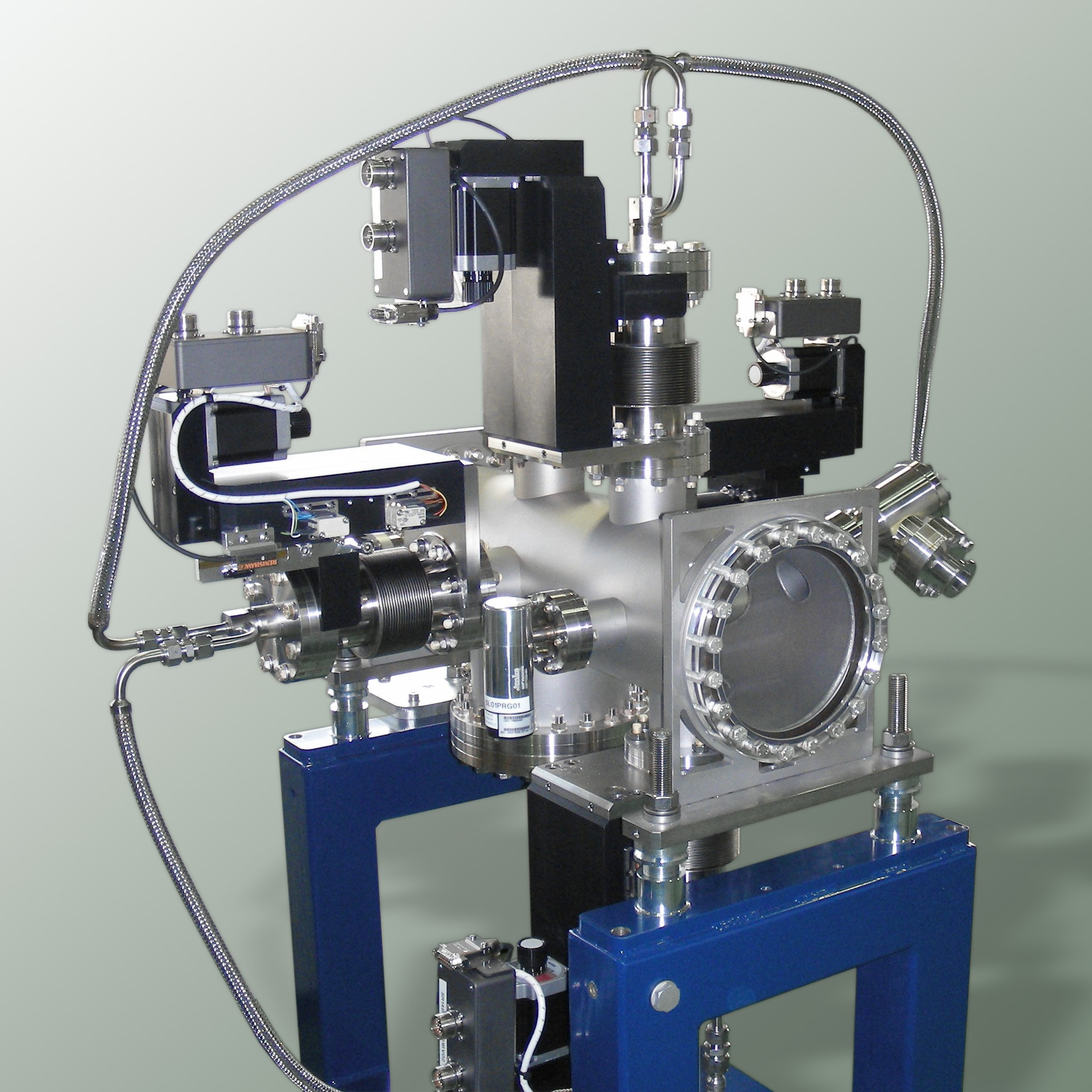

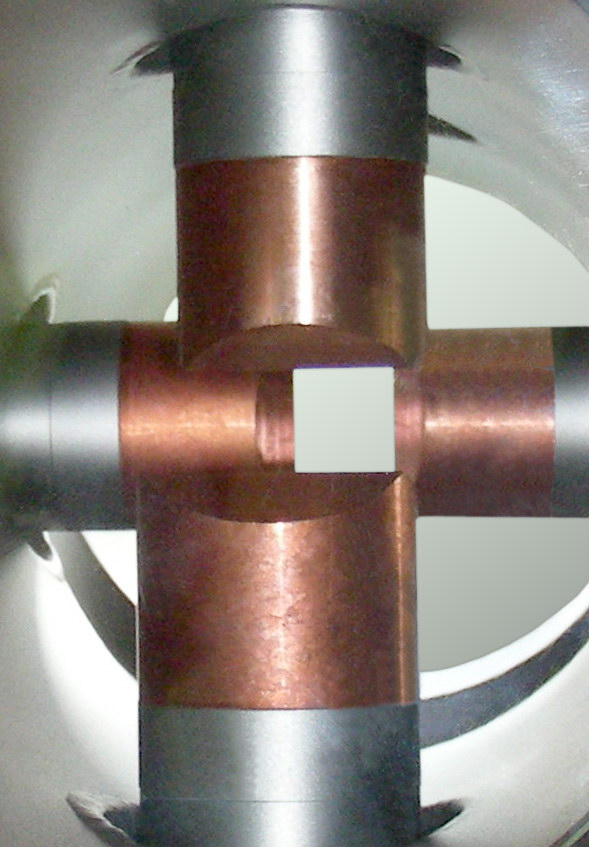

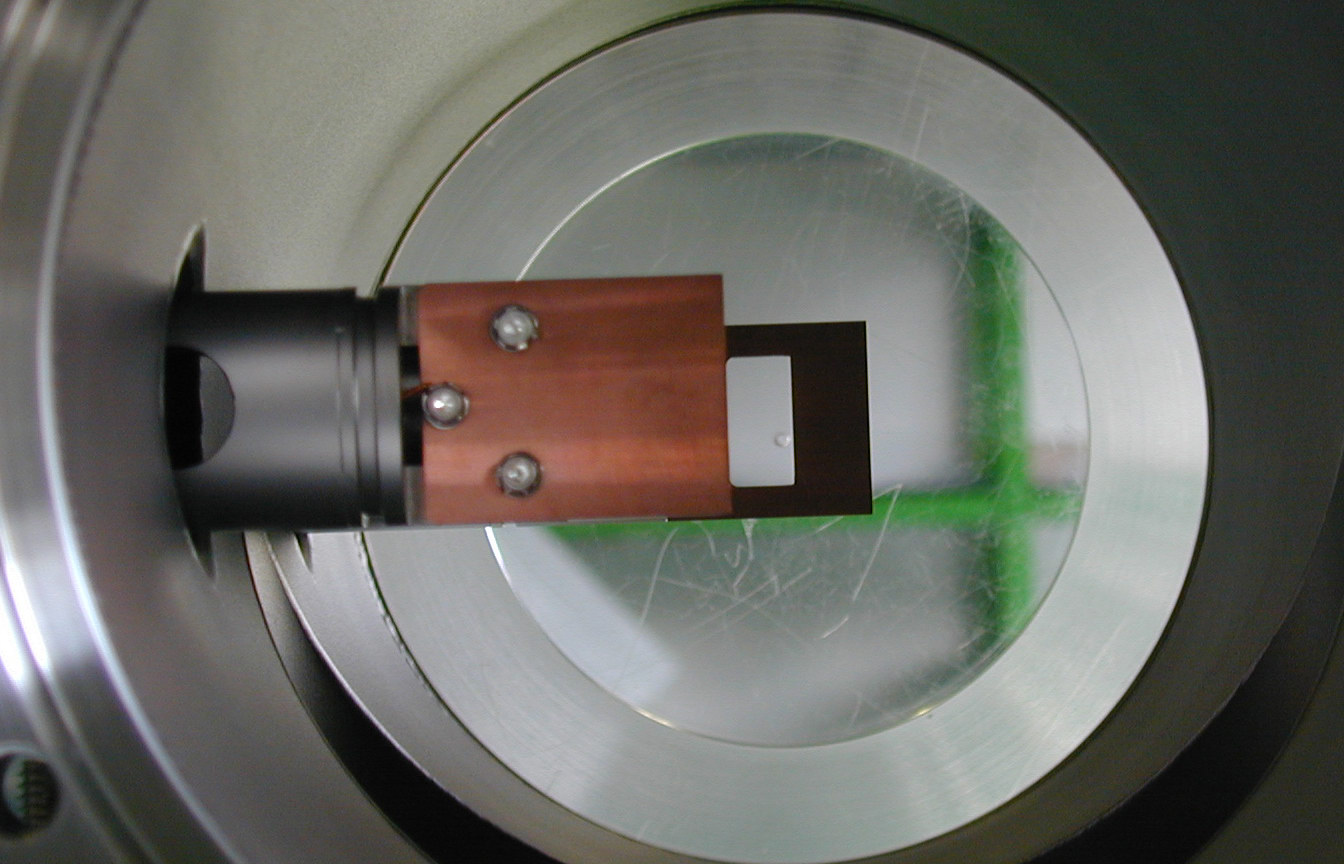

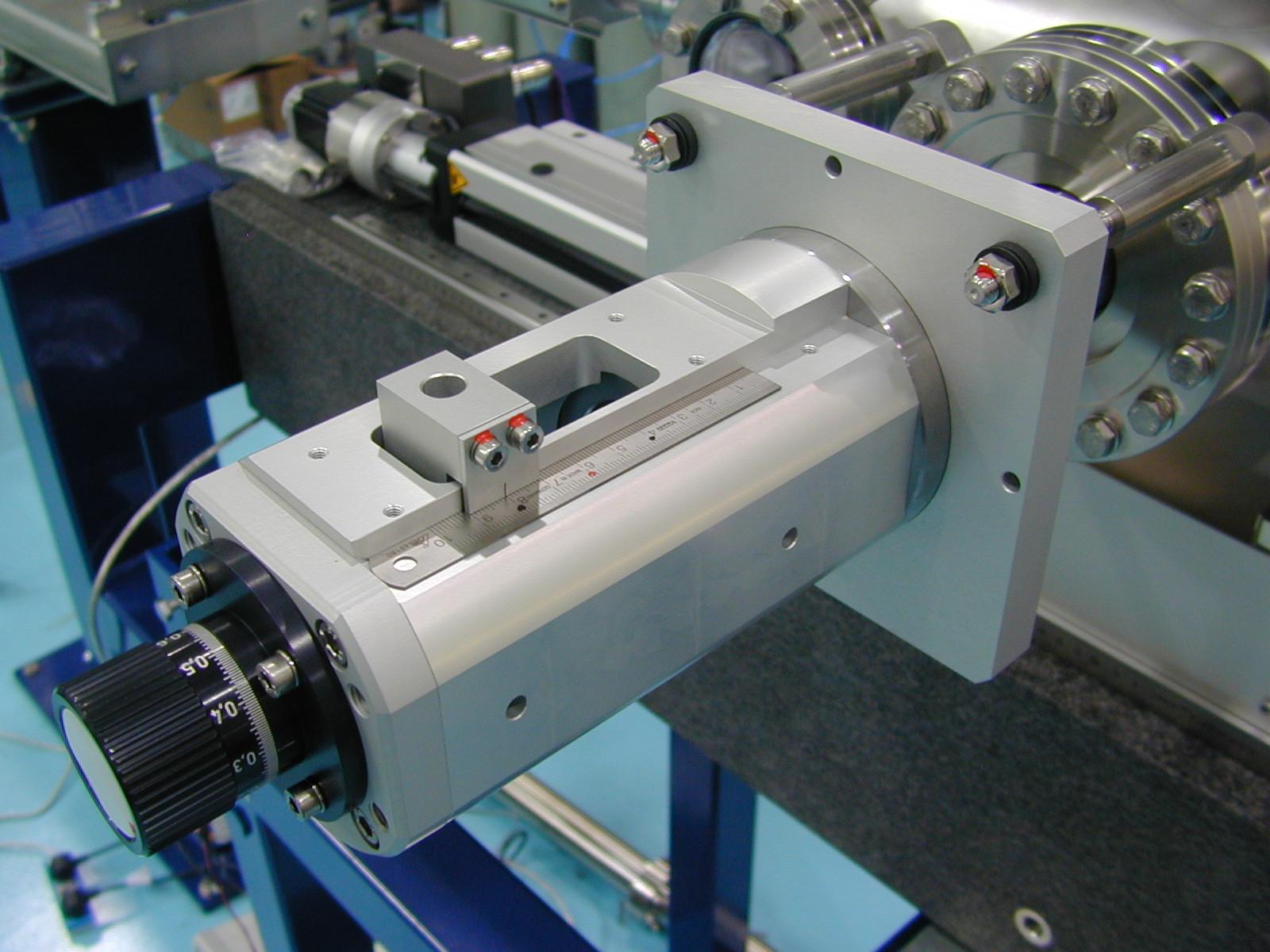

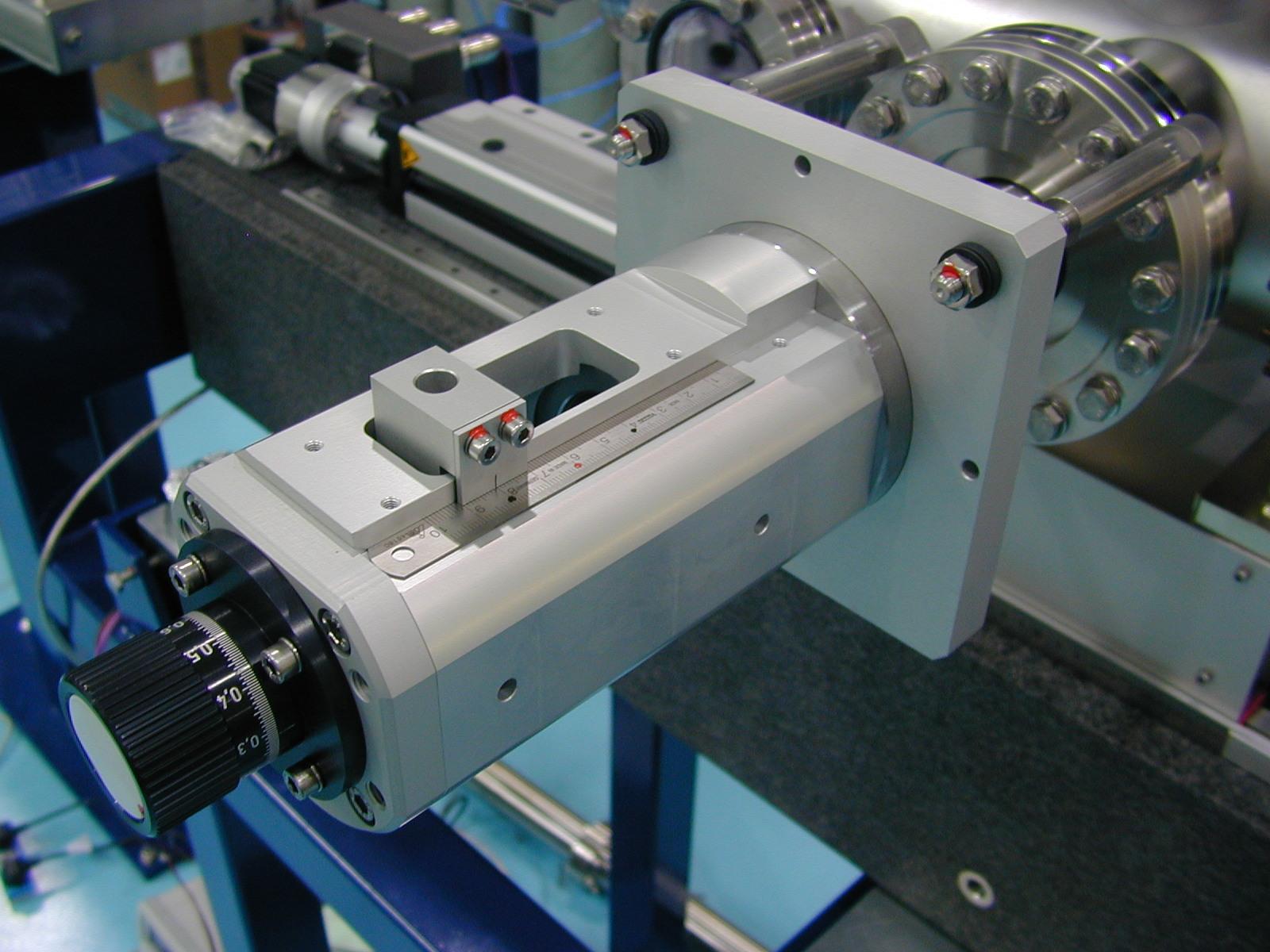

Each system consists of two or four slit heads and manipulators.

The slit system is based on a uniform and modular concept with

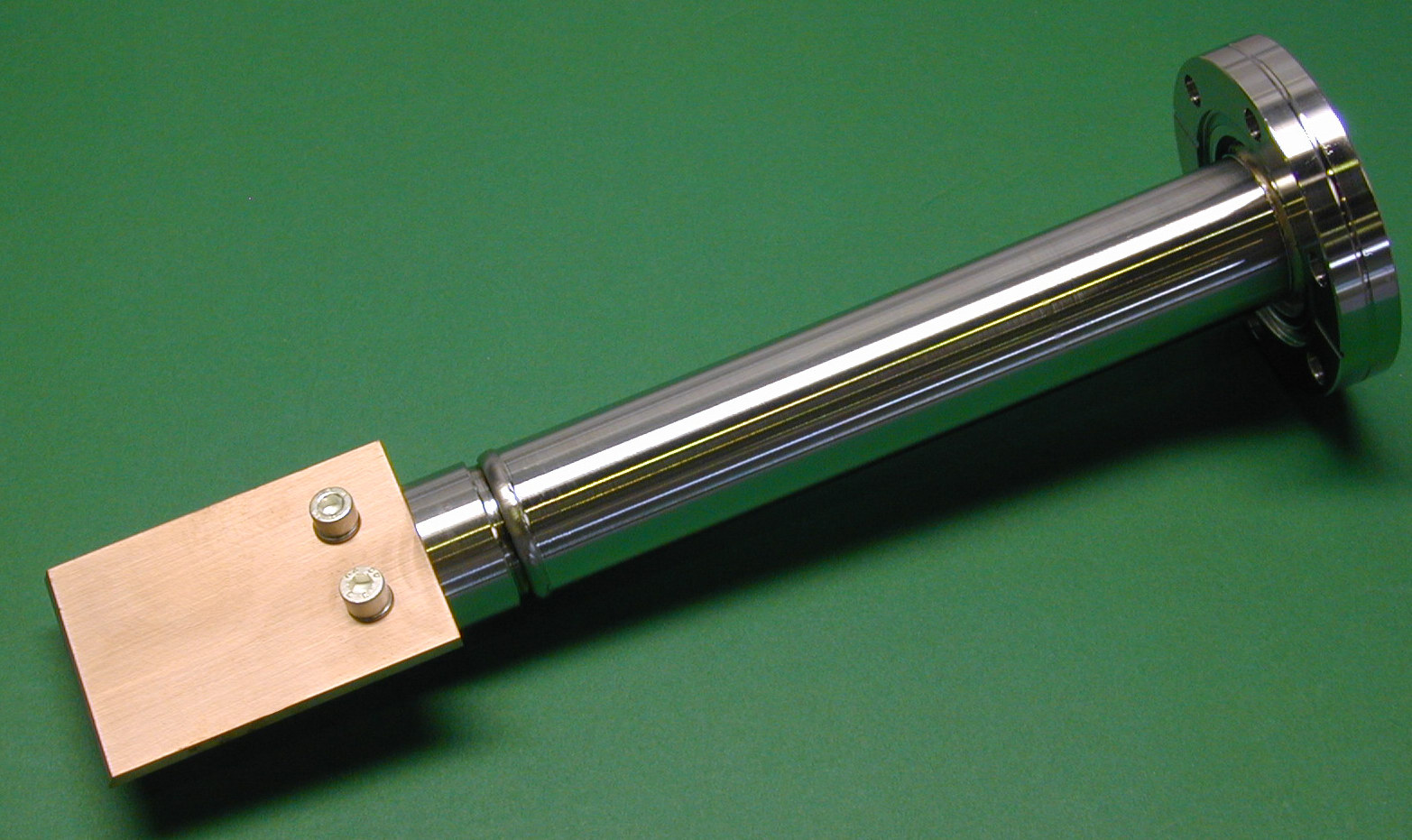

- stroke unit optionally driven by stepping motor with or without synchronous belt gear

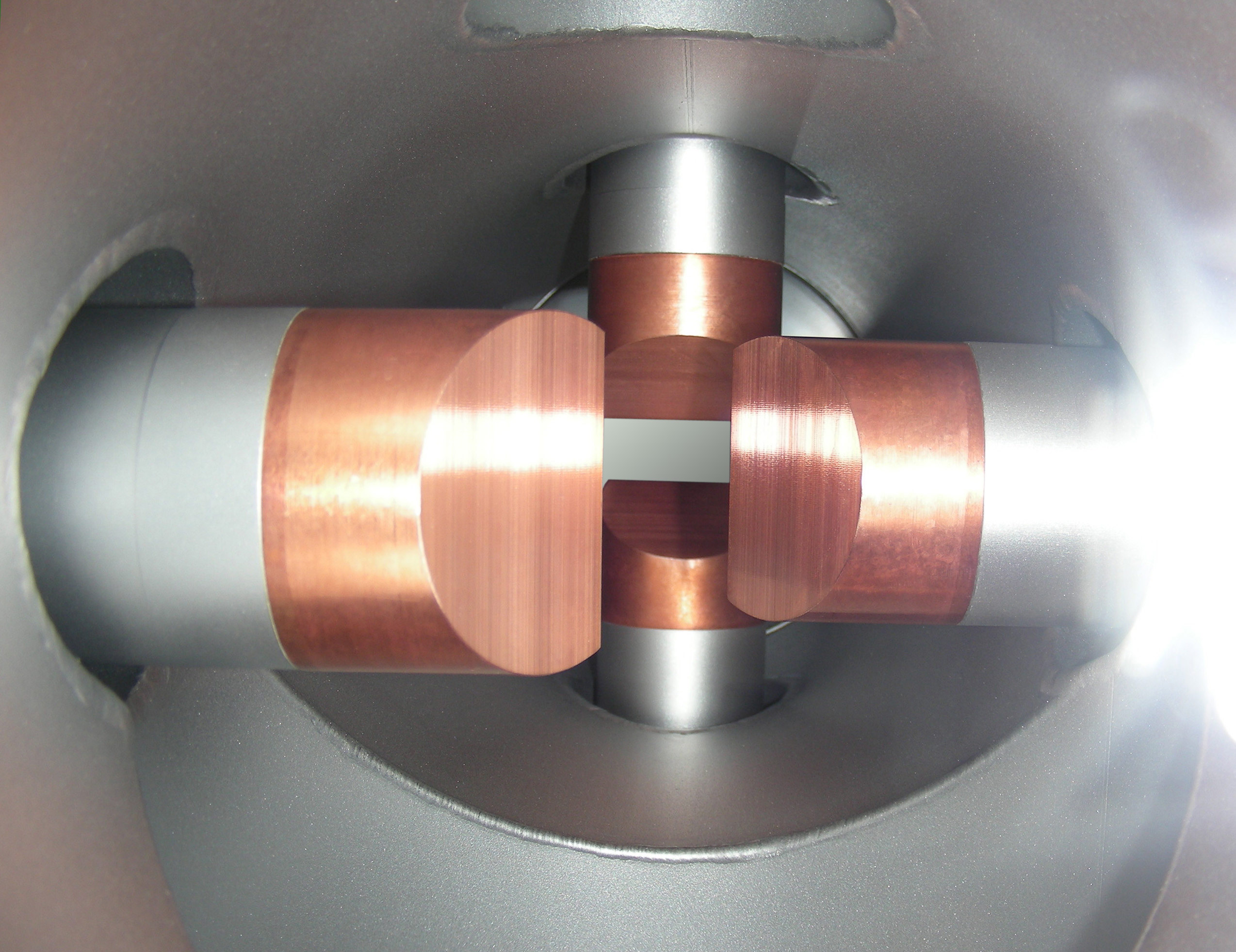

- cooled or uncooledslit jaws made of OFHC-Copper, Glidcop® or Tungsten

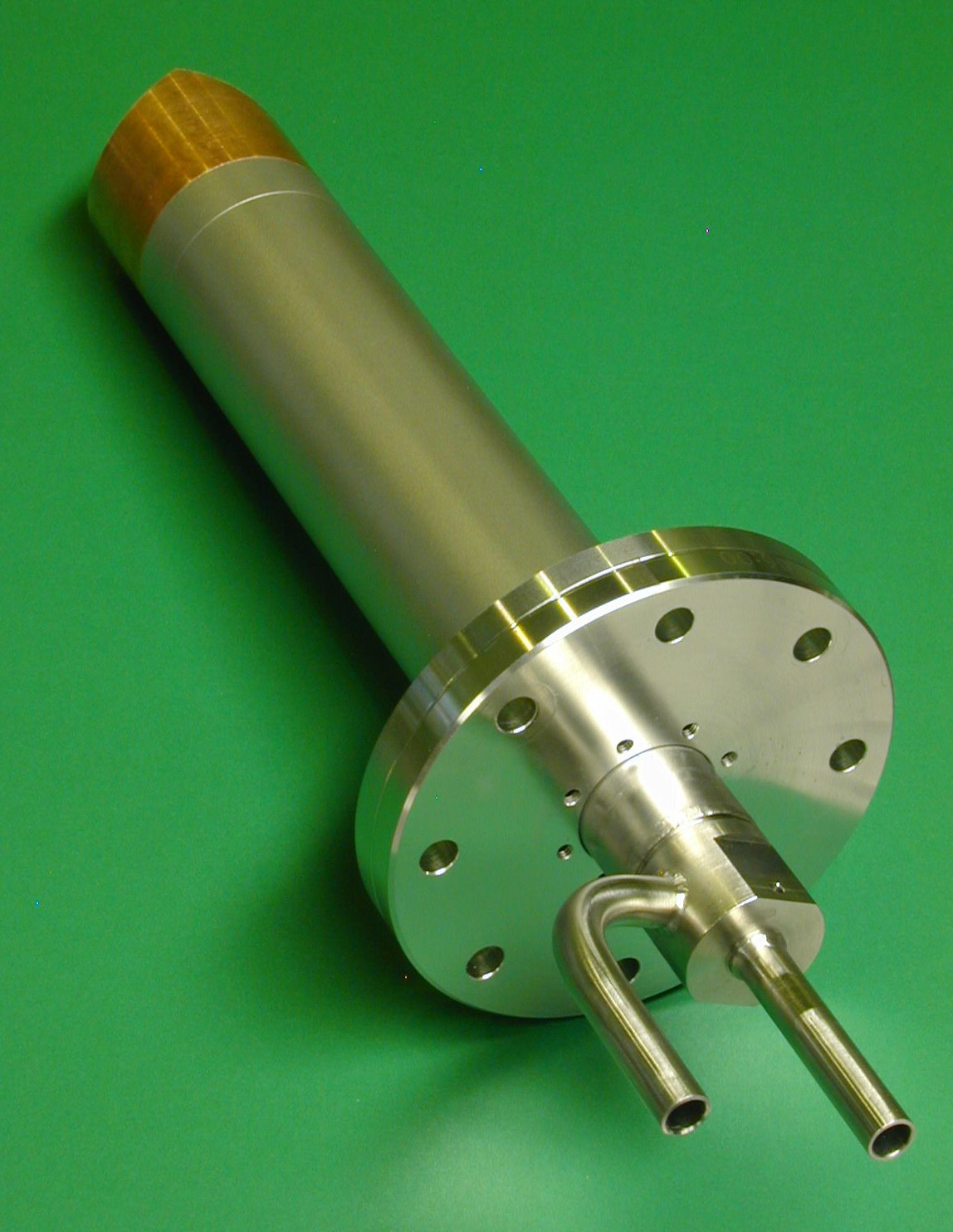

The linear drive system is mounted on a base flange CF63 or CF35. The system can be equipped with limit switches, reference switches or linear encoders. The manually driven or motorized linear feedthrough to the vacuum is realised by a welded bellows (size 63 or 35).

Depending on the heat load and the slit precision various slit heads can be connected to that interface flange on the vacuum side.

A standard slit head consists of e.g. an inclined Copper or Glidcop®plate with water cooling on the backside.

In case of a high thermal load a Tungsten cutting edge is inserted into the copper plate. For temperature control of the slit head a thermocouple can be fitted as an option.

As an further option FMB offers the drain measurement on the insulated aperture blades.

Technical Data:

| Dimensions of manipulator slit system: - Width (with synchronous belt drive) - Height |

250 mm 325 mm outside basic flange for stroke |

|

| Base flange: | 63 CF or 35 CF | |

| Slit blade length (max.): | 55 mm for 63 CF 32 for 35 CF |

|

| Cooling: | Watercoolingasoption | |

| Drain current measurement: | as option | |

| Drive: | Manually or motorized | |

| Motorization: | Stepper motor, 400 full steps | |

| Stroke: | ± 12.5 mm, ± 25 mm, ± 50 mm | |

| Resolution: | 0.005 mm per full step | |

| Repeatability: | 0.005 mm | |

| Repeat accuracy of reference point switch: | ± 0,002 mm | |

| Linear encoder: | Renishaw RGH 24 | |

| Reference switch: | Renishaw | |

| Limit switch: | MyComor Cherry | |

| Leakage rate: | < 1 x 10-10 mbar l s-1 |