Technical Description:

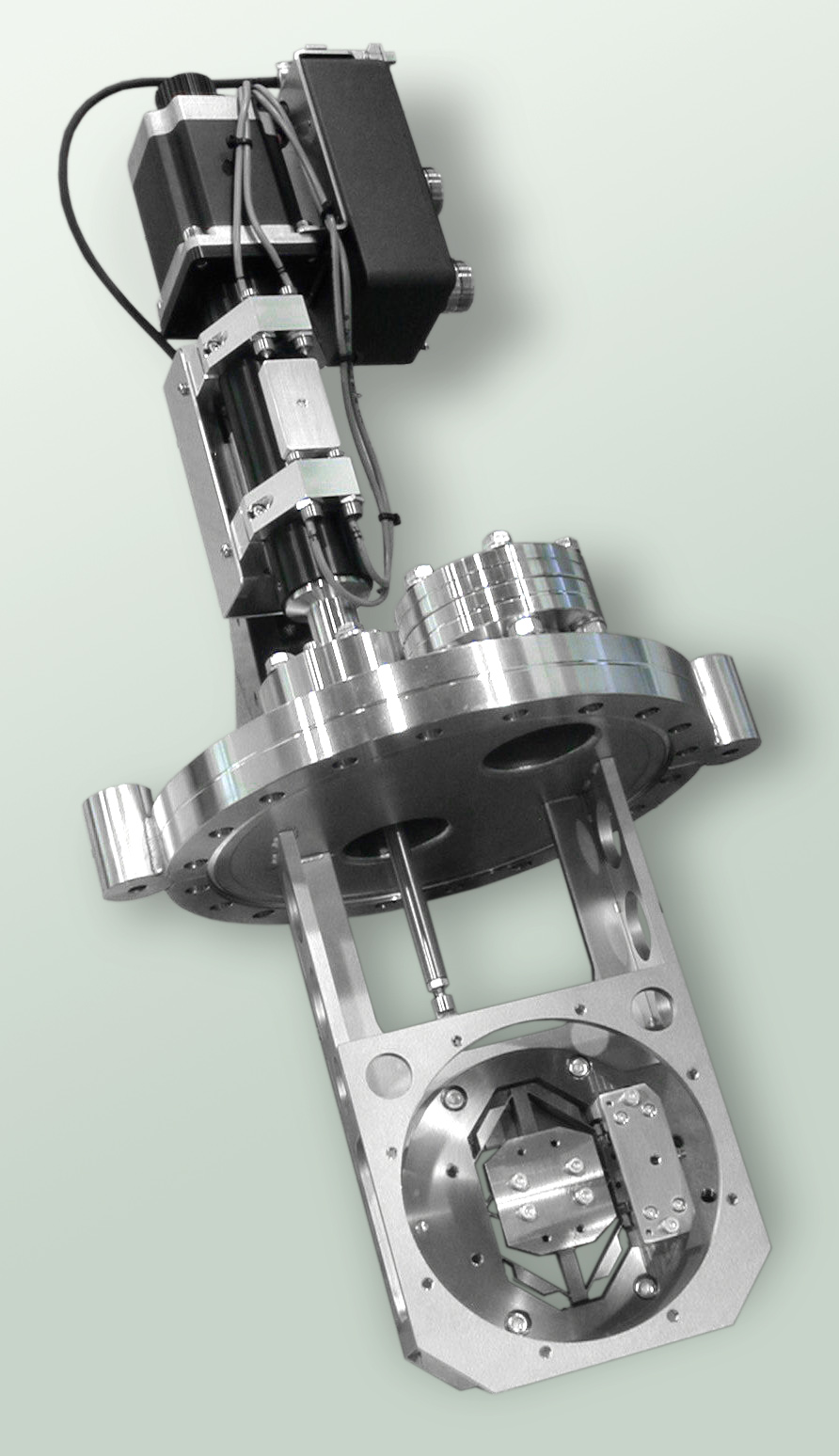

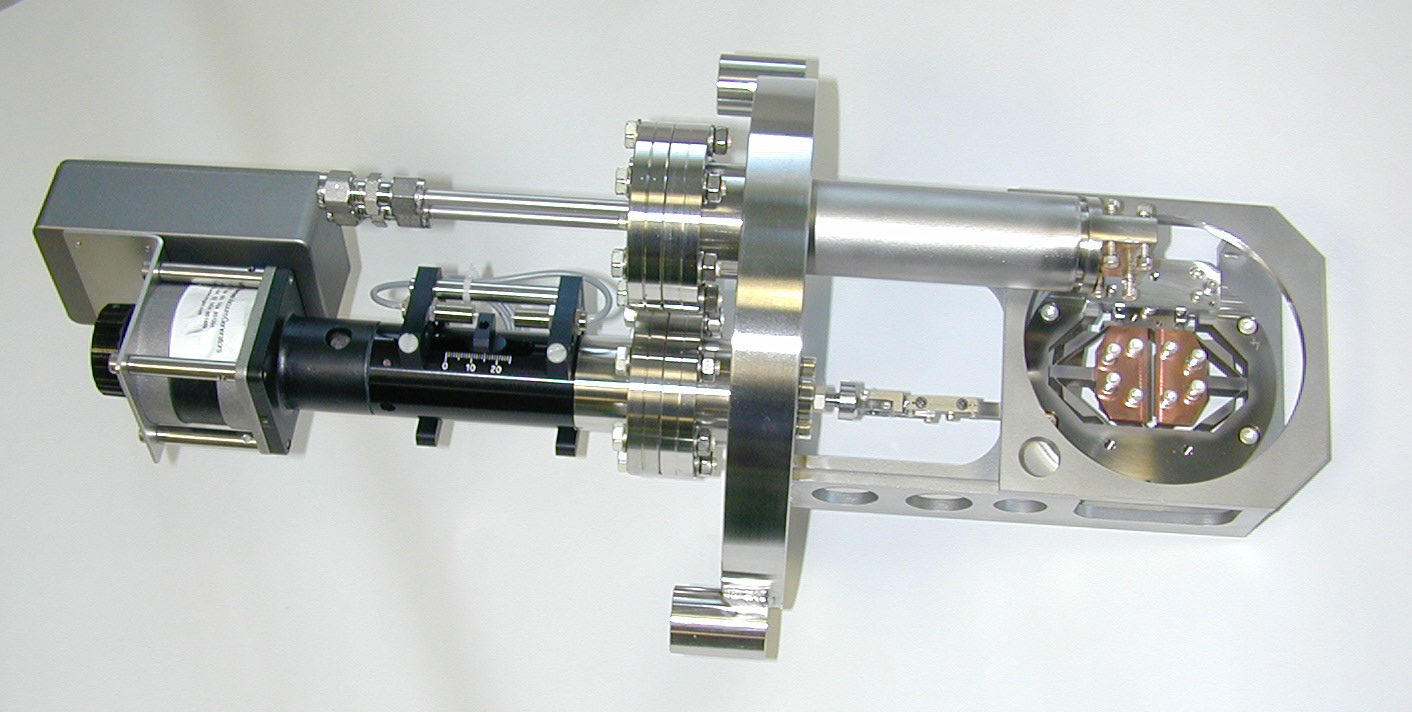

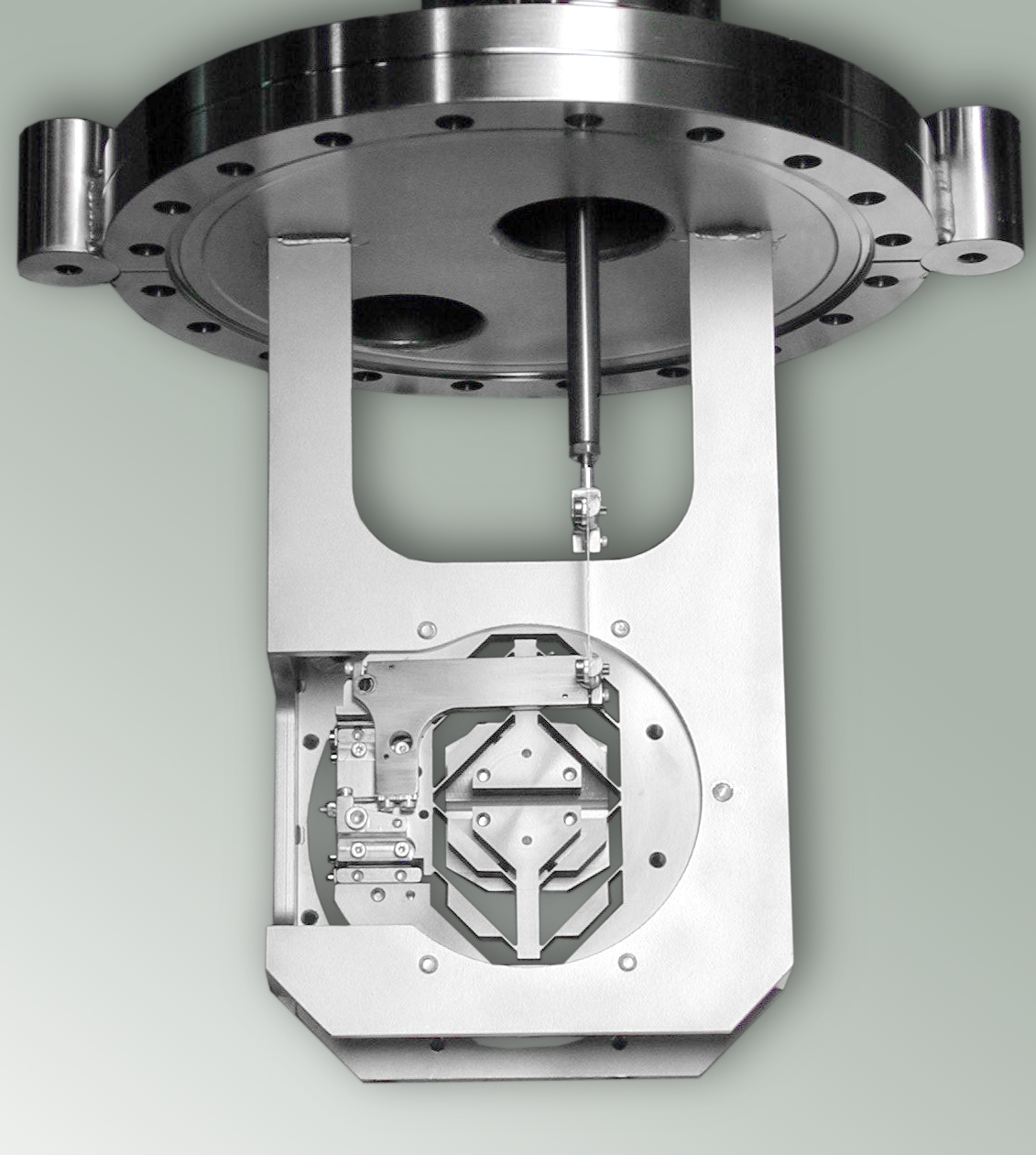

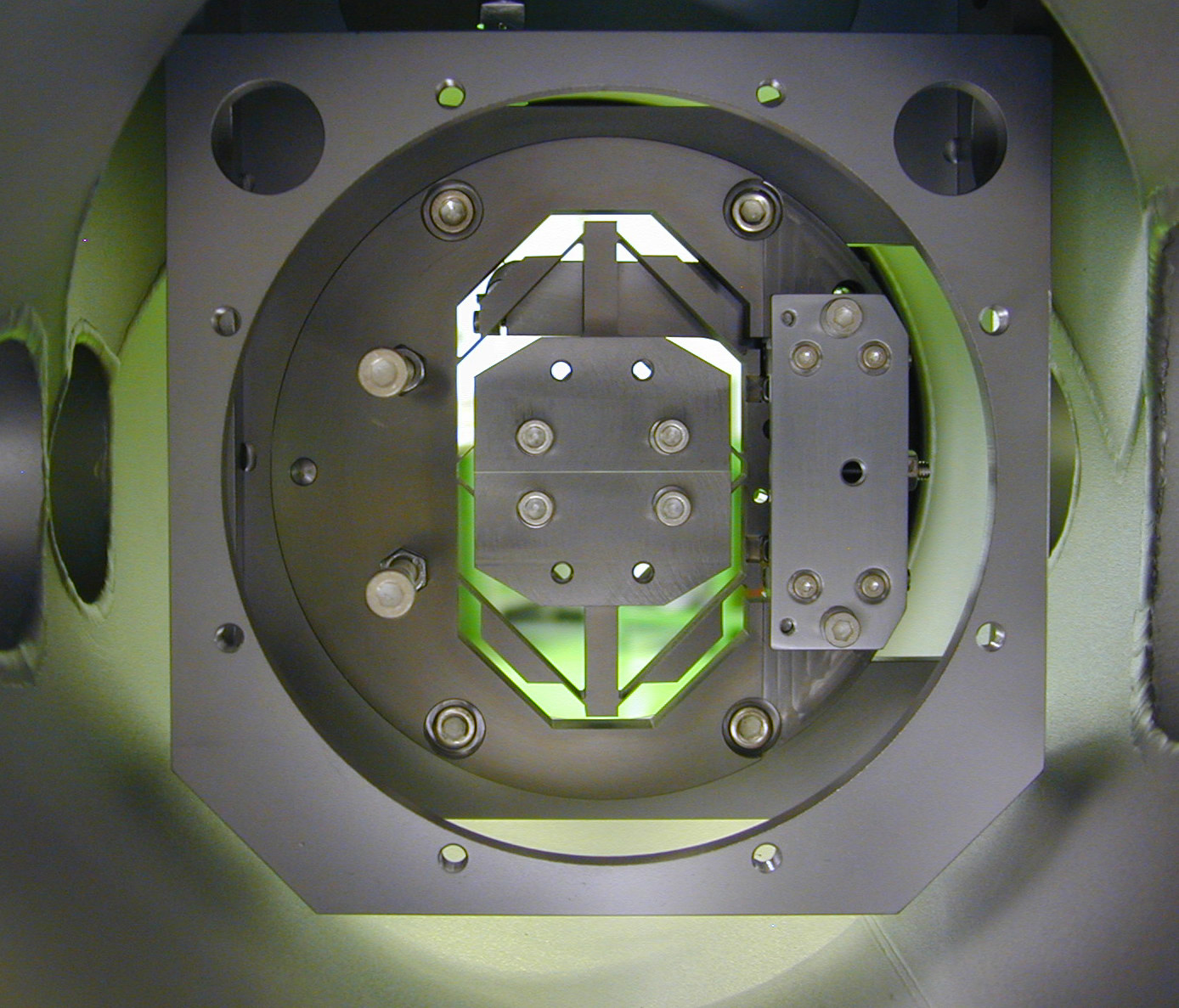

The precision slit assembly is a backlash free spring pivot system allowing an accurate symmetric and parallel opening and closing of the two slit jaws. It is driven by one single linear feedthrough.

This precision feedthrough can be chosen as manual or motorized type. The motorized type is driven by a stepper motor.

The slit assembly is mounted on a CF150 base flange which has fiducial holes on its air side for alignment and surveying. Water cooling of the slit jaws and / or their electrical insulation for drain current measurements are possible options.

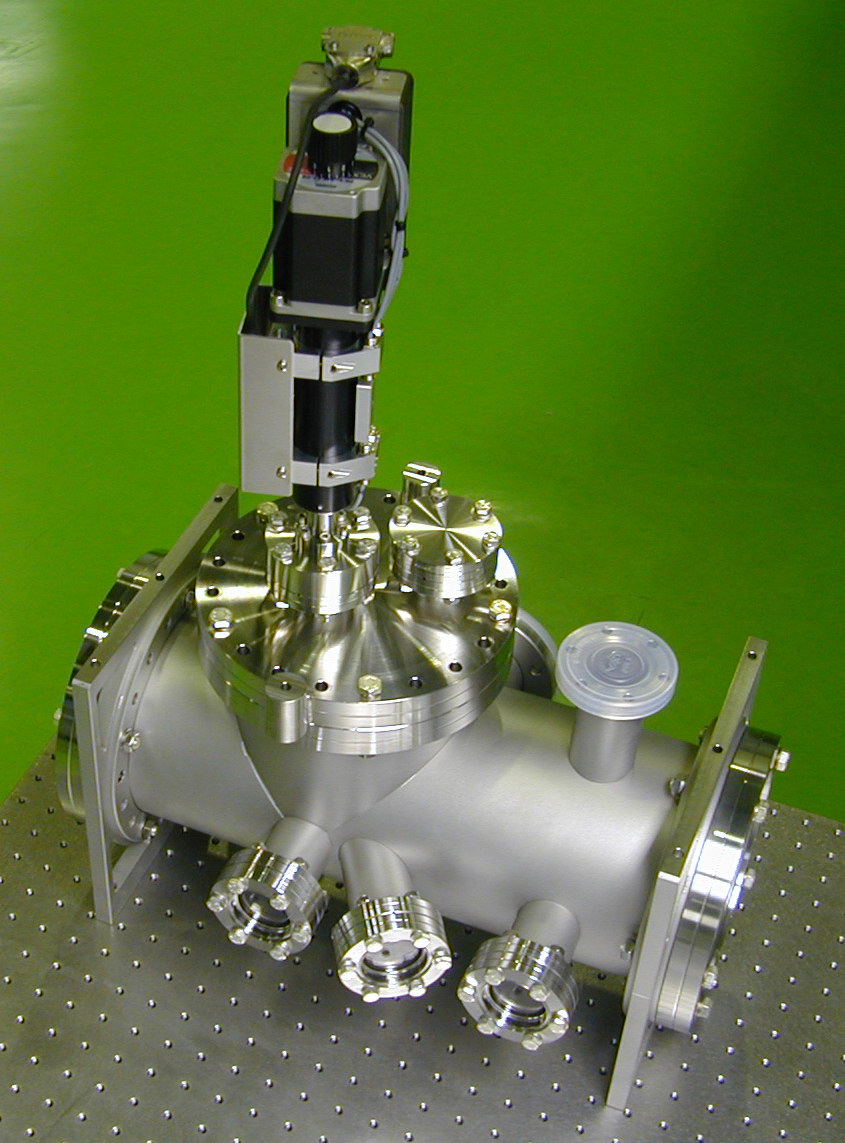

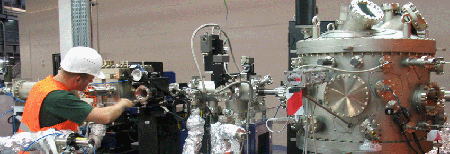

The slit chamber has a nominal size of 150CF and can contain several other ports for a pre-aperture, viewports, fluorescent screens and an ion pump a.s.o.. The whole slit chamber can be moved along the beam direction by a manual or stepper-motor-driven precision linear guide system. The necessary length compensation is realised with welded bellows upstream and downstream of the slit chamber.

The linear guidesystemissupportedbya rigid steelframesupportora block made of concrete or granite. They allow an accurate alignment of the slit system with respect to the beam axis.

Technical Data:

| Slit subassembly - Slit opening range - Repeatability of the slit opening - Step size of the slit opening ..(with stepper motor linear feedthrough) - Slit jaw length - Slit jaw parallelism |

0...3 mm < 3 µm < 1 µm / step 30 mm < 3 µm |

|

| Linear system for travel parallel to the beam - Beam direction stroke - Positioning accuracy - Travelling accuracy |

Up to ± 500 mm ± 0.2 mm ± 10 µm |

|

| Support - Elevation and lateral adjustment range of the ..adjustment elements - Adjusting elements accuracy |

± 10 mm ± 0.05 mm |

|

| Nominal width of ports - Pump flange - Entry and exit flange or membrane bellows |

DN 100 CF DN 35 CF Option: DN 63 CF |

|

| Slit cooling - Indirect water cooling using flexible copper braids |

as Option |

|

| Drain current measurement - Using floating shields feedthroughts and ..Aluminium-Nitride insulation |

as Option |