Technical Description:

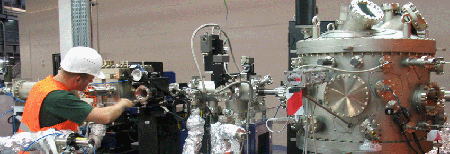

FMB has a long experience with building adjustable apertures and masks for synchroton sources worldwide.

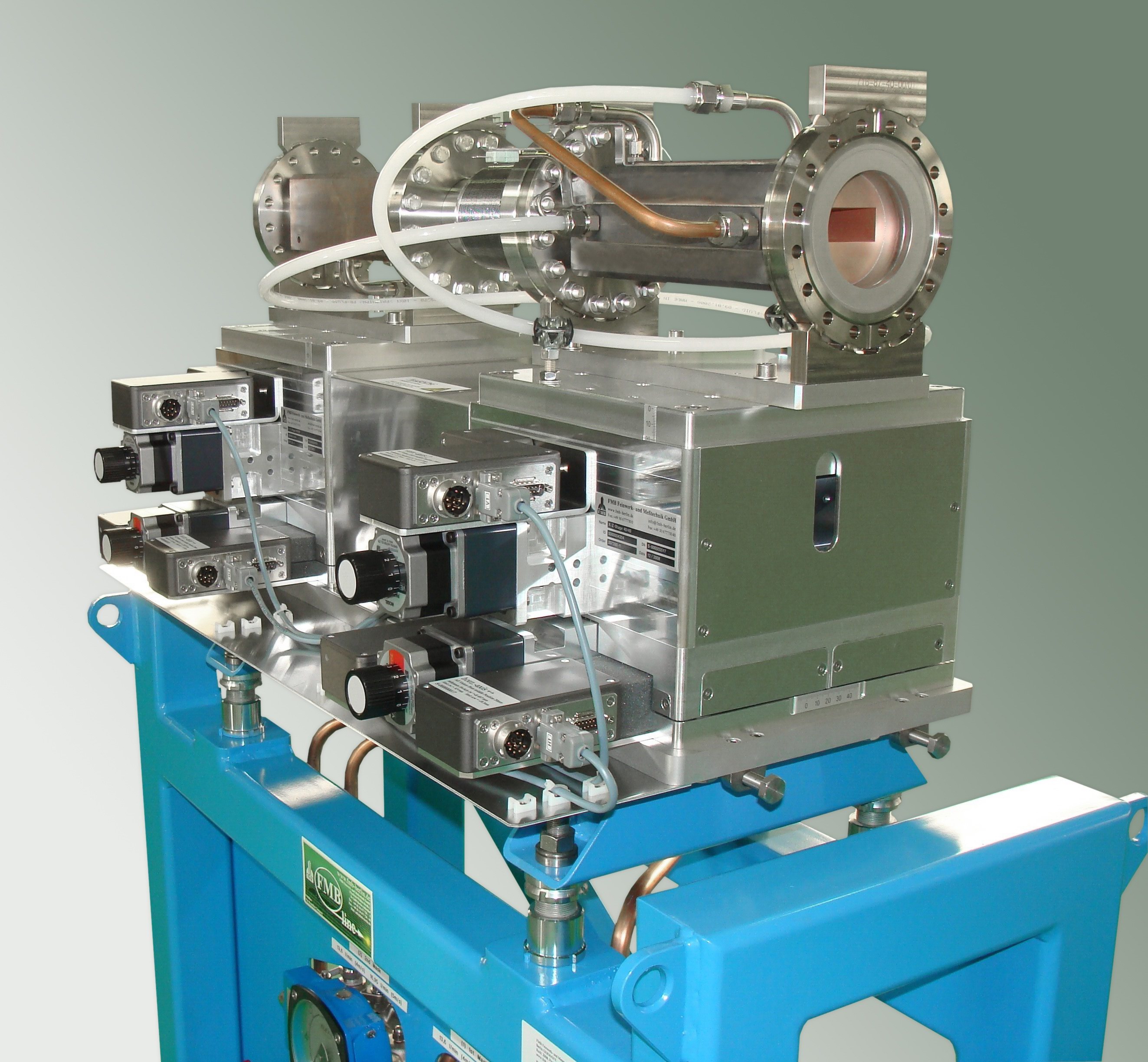

FMB produces apertures for high heatload, needed in the white beam as well as for low power applications needed in the monochromatic beam.

Depending on the application and the beam power, these apertures are either cooled or uncooled and available in different size and different precision. Total power load, power density and aperture size are the main parameters defining the design of the system.

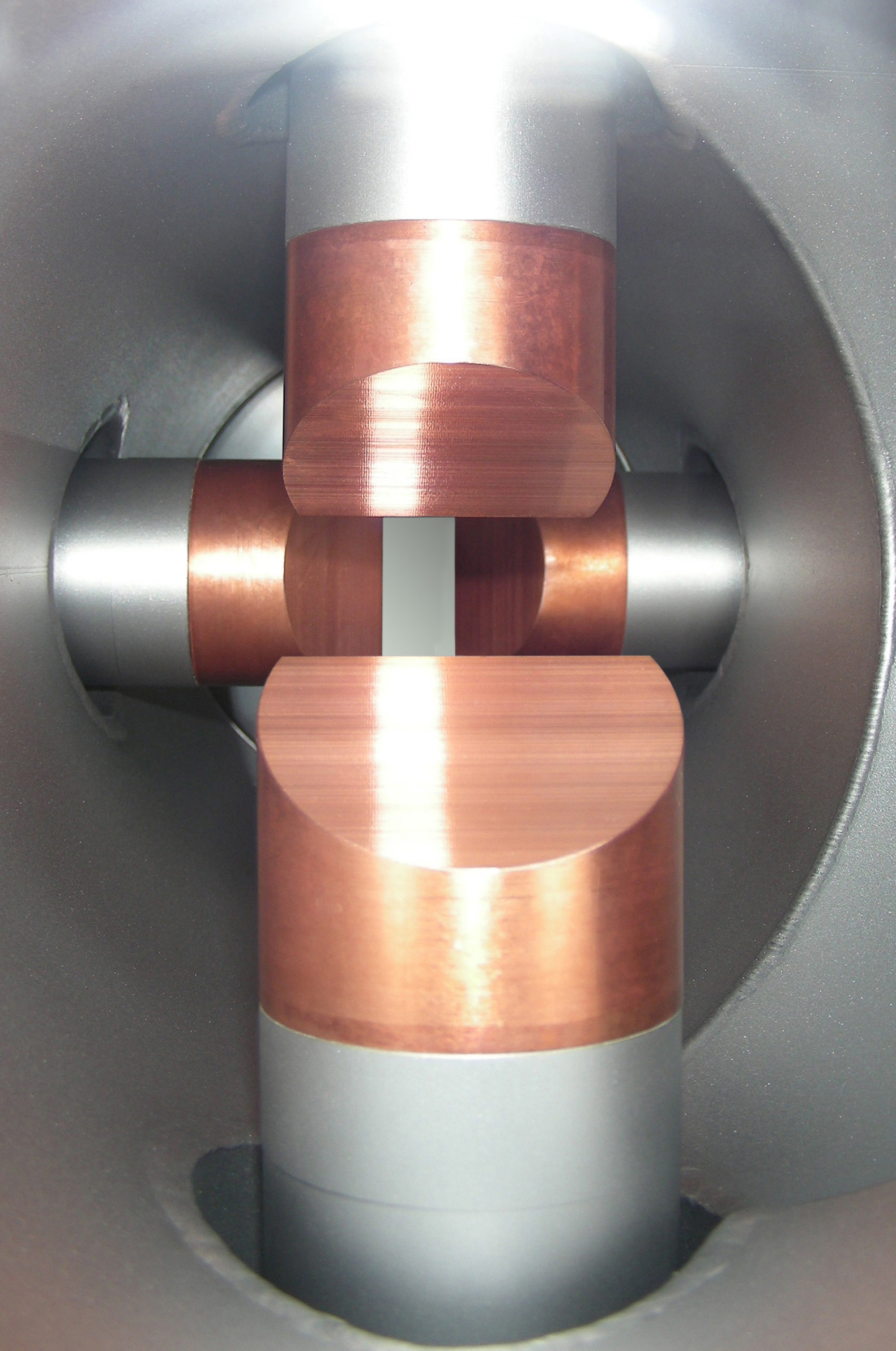

Electrical isolated blades or blades equipped with additional fluorescent material are also available.

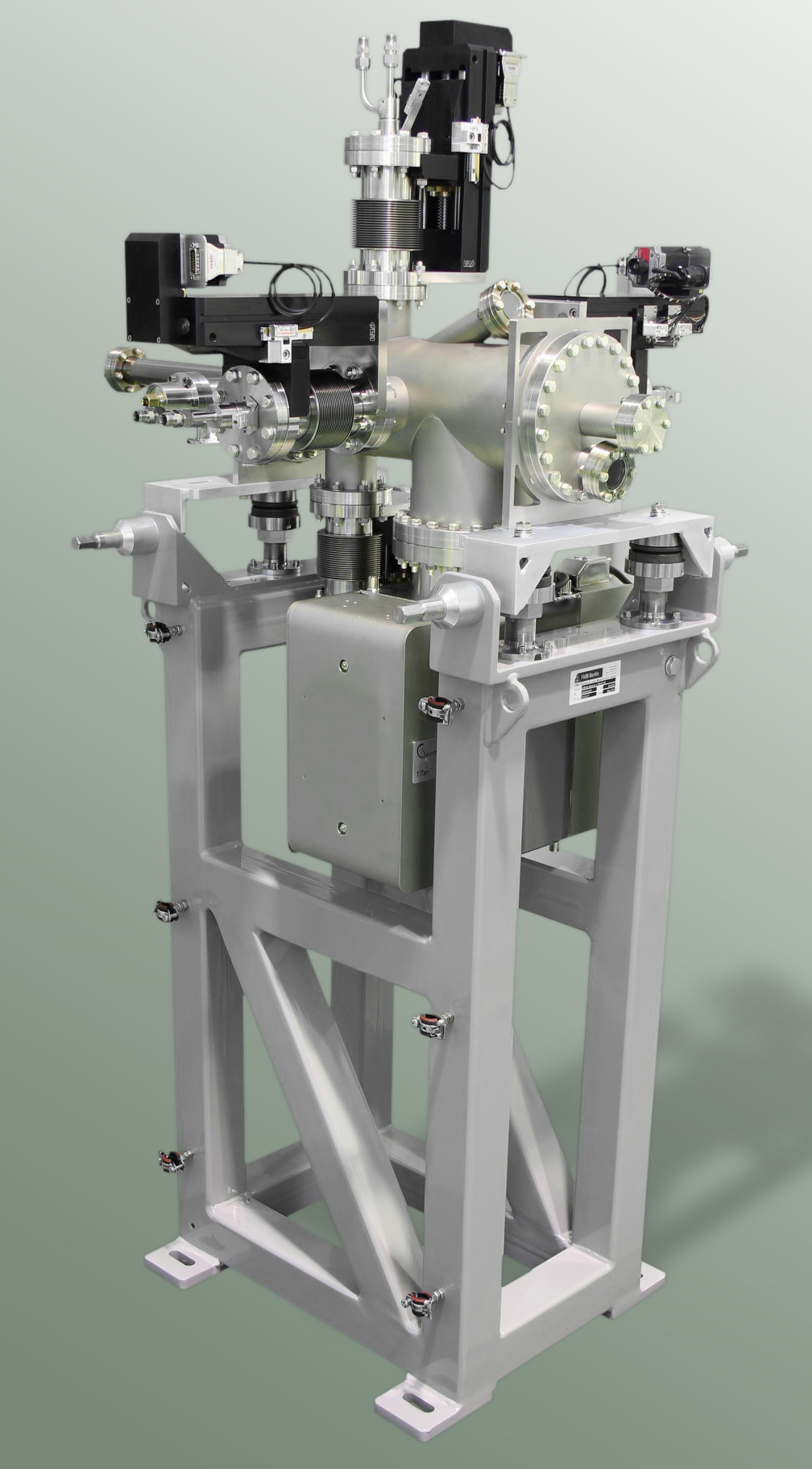

Several support types are available, e.g. supports built from welded steel frames as well as highly stiff and rigid granite or concrete based supports.

The range of adjustable apertures and slits for synchrotron radiation made by FMB can be devided in:

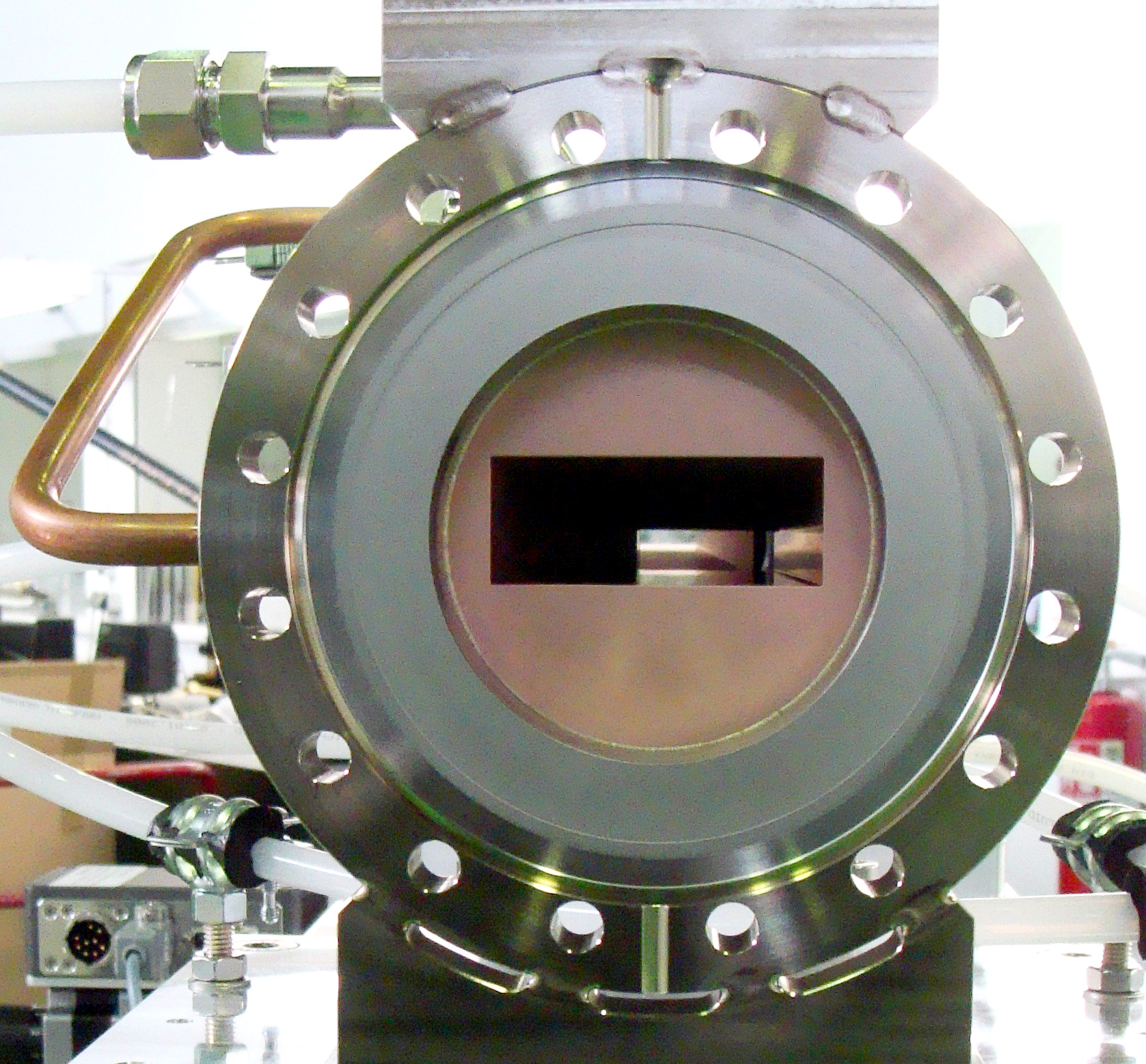

- Very space saving uncooled in-flange-systems

- Systems with two parallel blades each controlled by one linear actuator, mounted on one common base flange

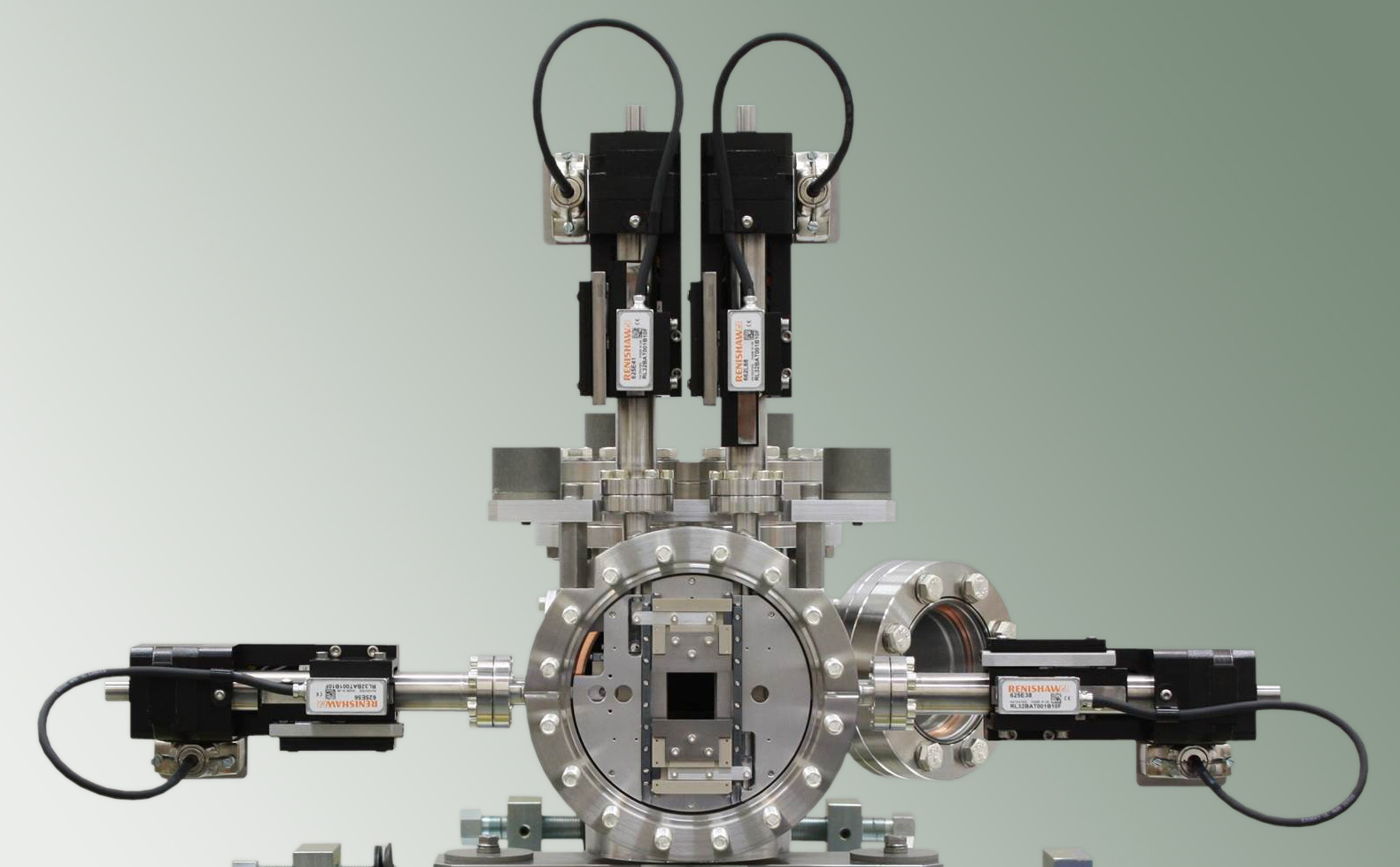

- Systems with up to four separate blades each mounted with its own linear feedthrough on a vacuum chamber

- Two movable masks mounted on top of two motorized transversally and vertically moving stages

Technical Data:

| Blade material | OFHC-Copper, GLIDCOP®, (other materials on request) | |

| Maximum power | up to 15 kW (depending on design) | |

| Maximum power density | up to 150 W/mm² (depending on design) | |

| Blade edge length | from a few mm up to more than 100 mm | |

| Stroke | from a few mm up to more than 100 mm | |

| Drive | stepper motor or manually driven | |

| Fullstep resolution | usually a few µm/full step, depending on the actuator | |

| Encoder resolution | 1 µm/count (other resolutions available on request) | |

| Repeatability | ≤ 2 .. 20 µm (depending on design) | |

| Vacuum compatibility | UHV (10-10 mbar) | |

| Baking temperature | 200 °C | |

| Options and parameters Which can be selected on request: |

|