Technical Description:

FMB has experience in building blade type X-ray beam position monitors (XBPMs). XBPMs made by FMB are widely used at many synchrotrons to measure the photon beam position at the micron level.

XBPMs made by FMB are widely used at many synchrotrons to monitor the photon beam position vertically and horizontally at the micron level for beam stabilization purposes.

The FMB XBPM design is a joint development of Karsten Holdack (HZB, formerly BESSY) and FMB.

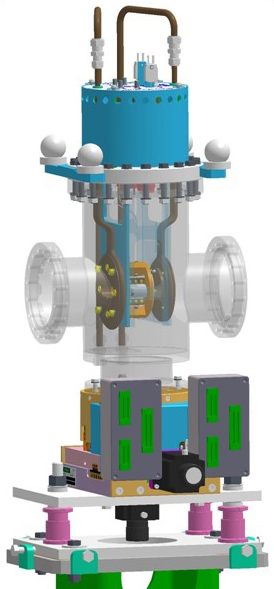

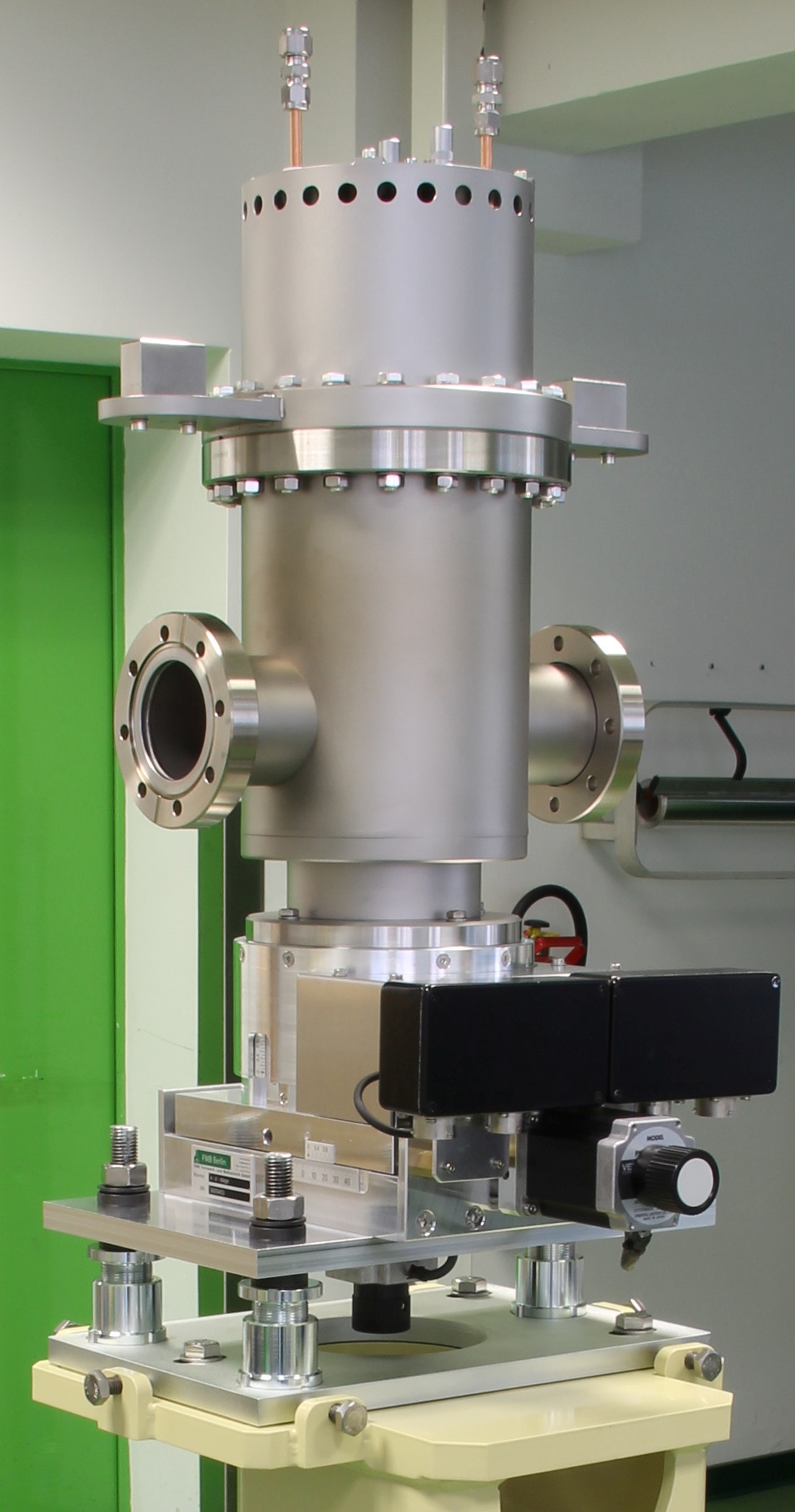

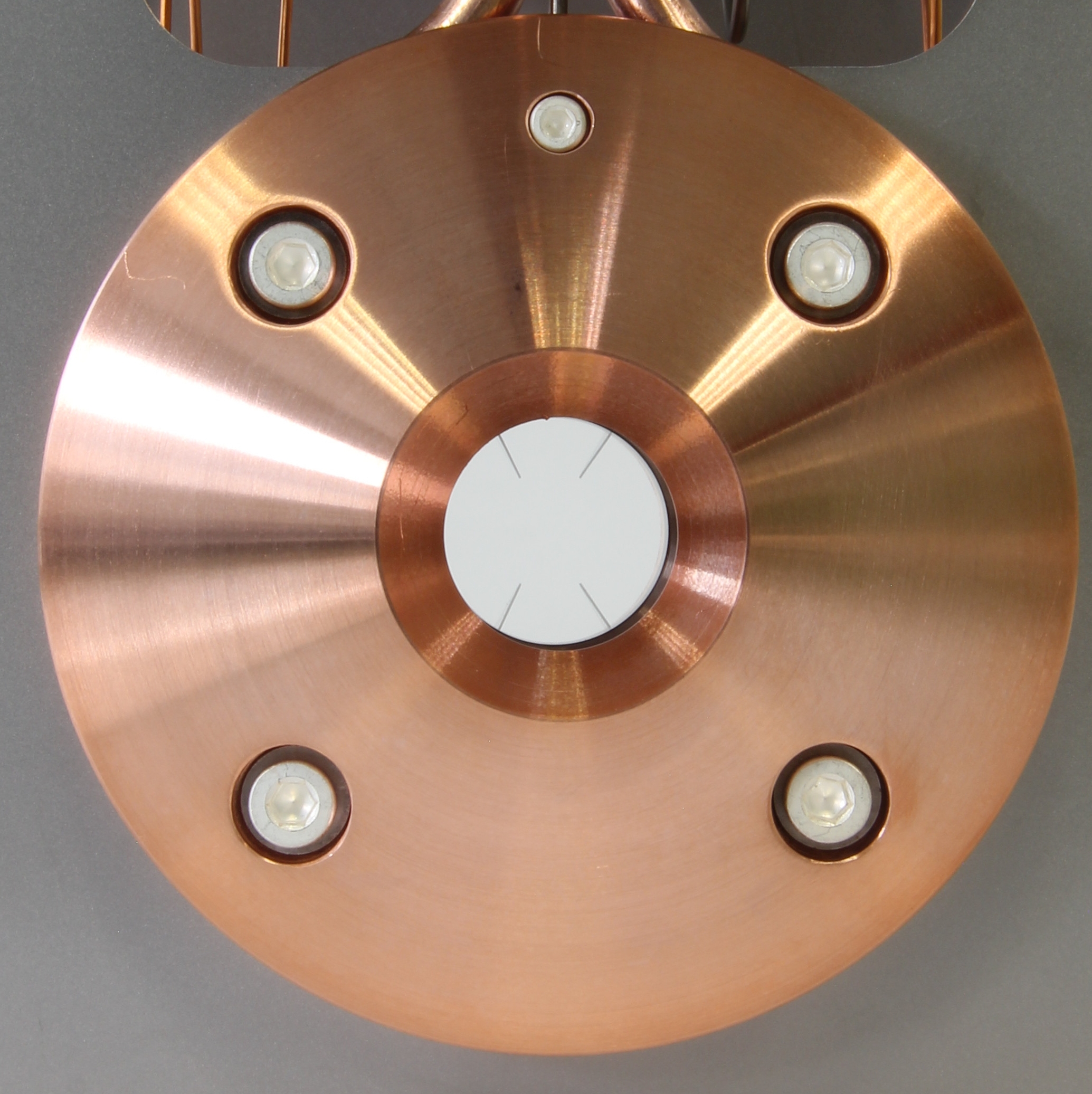

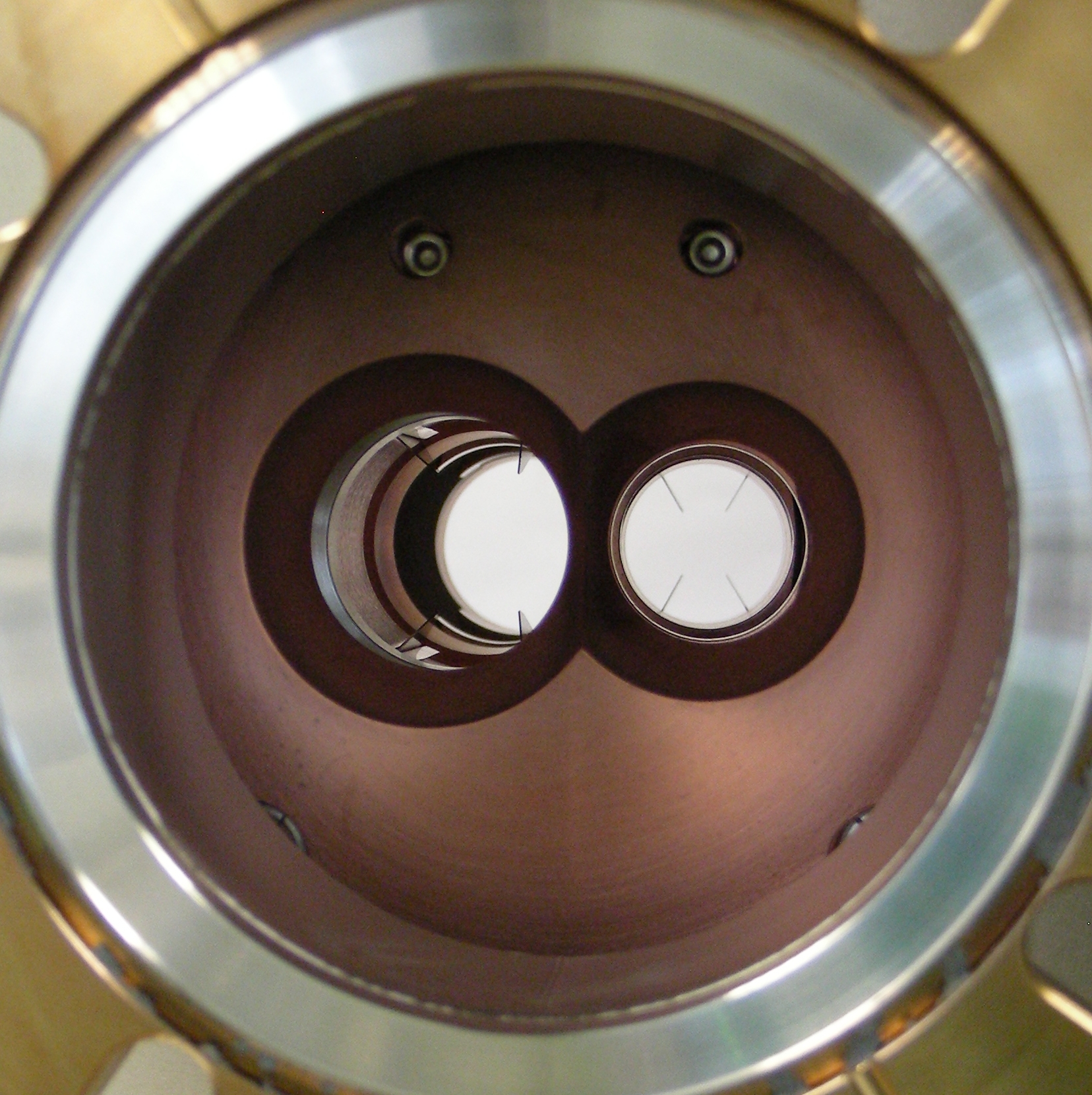

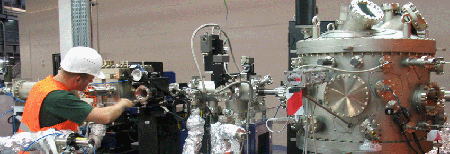

A typical FMB XBPM system consists of a XBPM insert, a vacuum chamber, a motorized precision X-Z stage, a X-Y-Z manual alignment assembly and a support. In addition FMB offers motion control hardware and software and signal processing / analysis electronics on request.

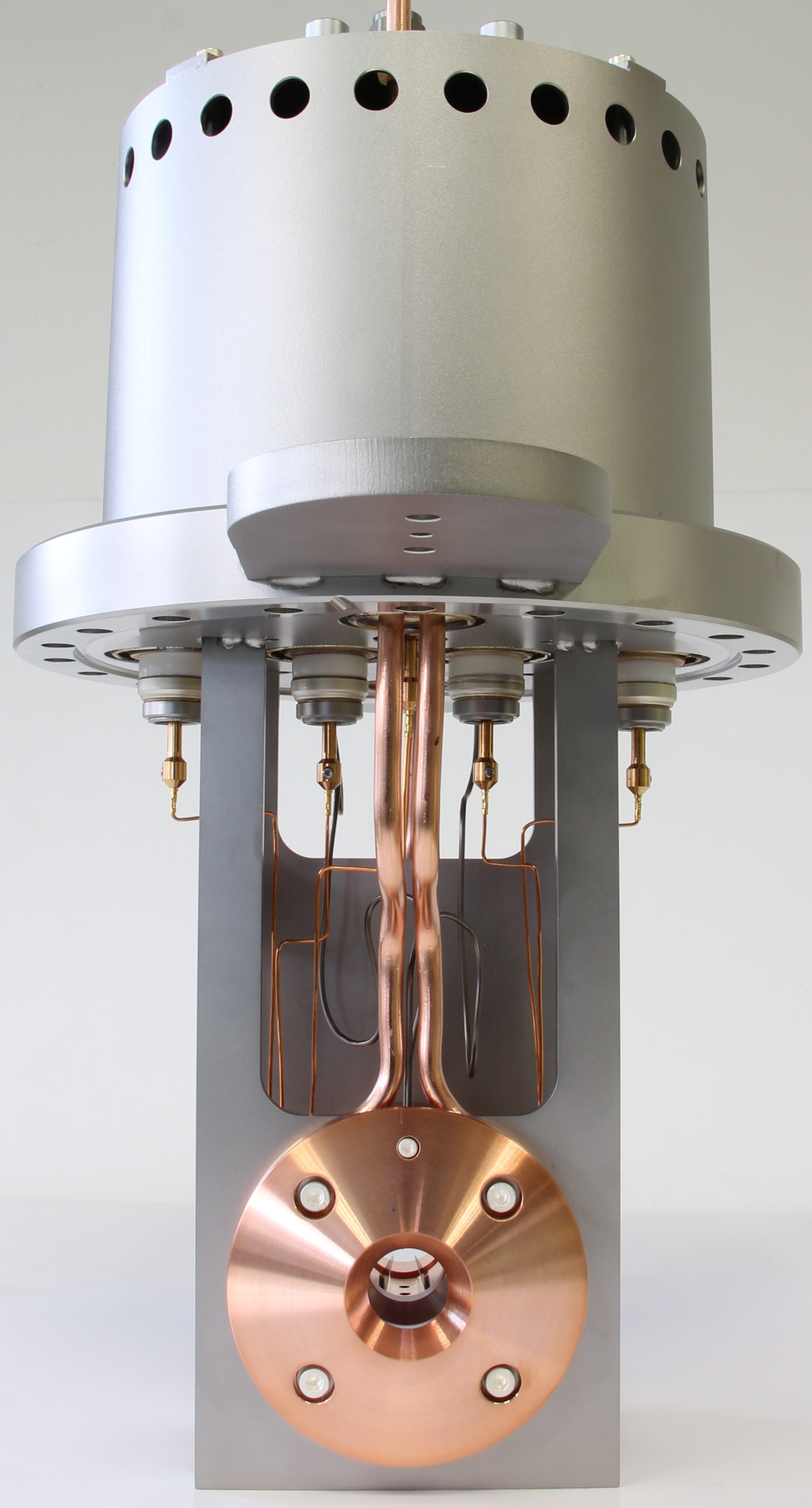

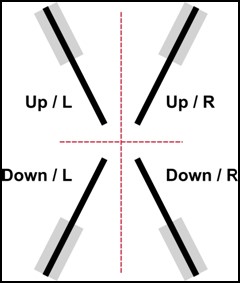

The XBPM beam position monitors use four blades, whose narrow fronts are oriented towards the radiation source. The blades are symmetrically arranged on a virtual X with its center close to the center of the radiation beam. With this blade setup the operator is able to scan the off-axis radiation of the source and determine on-line the horizontal and vertical position of the radiation source centre from the emitted signals.

Size and geometry of the blades will be adapted to the beam characteristics at the place of the position monitor in order to achieve a maximum photocurrent yield at a maximum sensitivity. The blades are made of Tungsten and cooled via heat conducting ceramics to resist the thermal load of the radiation source.

Technical Data:

| SPM insert | ||

| Type | Staggered blade pairs beam position monitor | |

| Number of blades | 4 | |

| Blade material | Copper / Tungsten | |

| Aperture / blade opening, | Suggested by FMB, | |

| blade thickness / pair offset | dependent on beam specifications at installation position | |

| Cooling | Water cooling | |

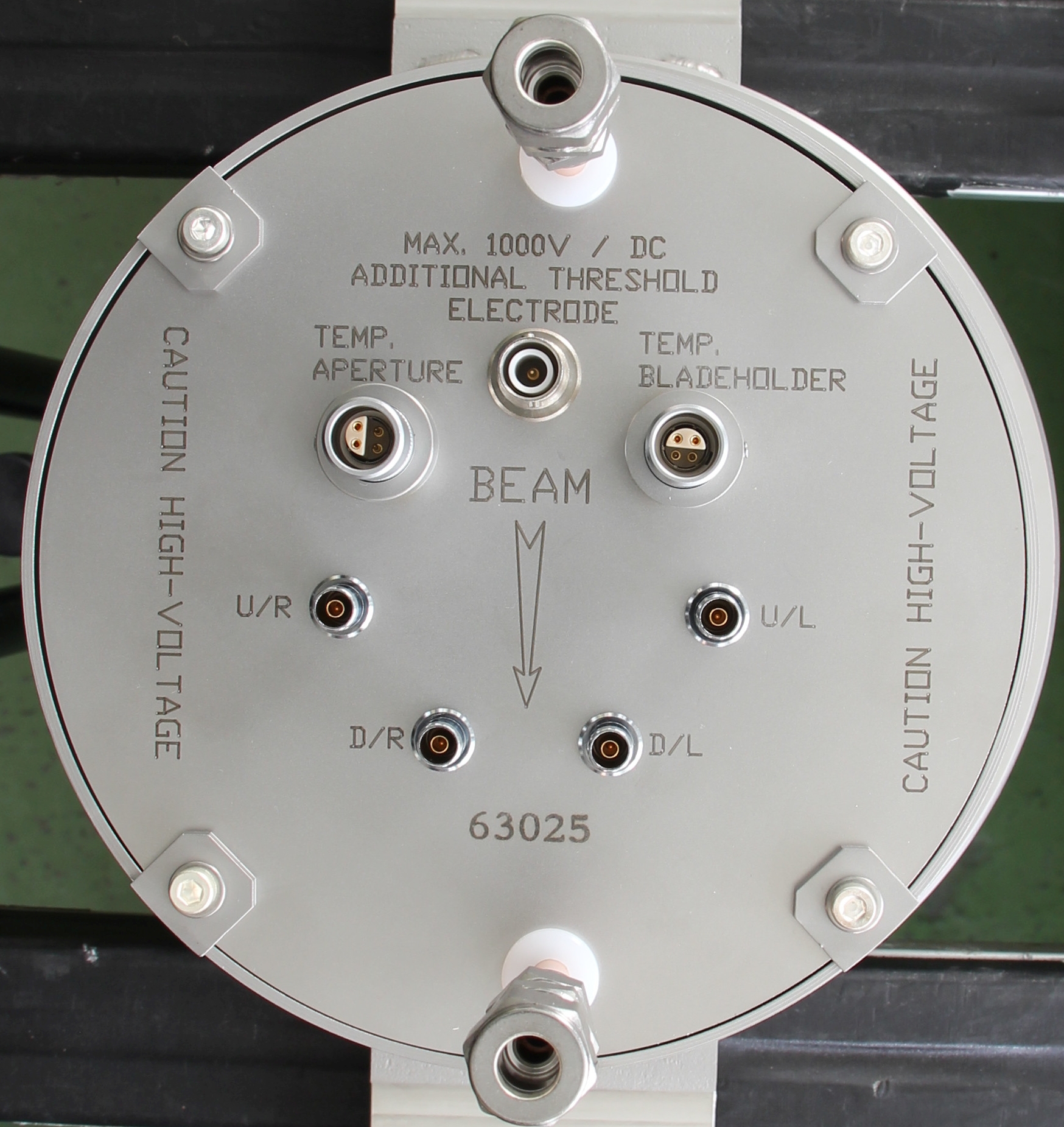

| Temperature measurement | Thermocouple K-type close to aperture | |

| Electrical strength | 500 V | |

| Feedthroughs | Triax, miniature TC flat pin (others on customer request) | |

| Base flange | DN 150 CF fixed | |

| Fiducials | 2 / 3 / 4 Hubbs or laser tracker supports at base flange | |

| Pinhole array (optional) | Design according to customer requirements, 0.02 mm min. pinhole diameter dependent on foil thickness |

|

| SPM chamber | ||

| Chamber / flange material | 1.4301 / 1.4429 (similar 304 / 316LN) | |

| Beam entrance /exit flange | DN 40 CF or different on customer request | |

| SPM insert flange | DN 150 CF fixed, oriented with respect to SPM insert | |

| Additional flanges | Optional on customer request | |

| Support | ||

| Column material | Steel (Invar on request) | |

| Fill | Dry sand | |

| Manual chamber alignment | Lateral ± 20 mm, vertical ± 12.5 mm, resolution. (l, v) < 0.1 mm | |

| Alignment via X-Z-stage | Lateral (X) ± 5 mm, vertical (Z) ± 5 mm, | |

| (optional) | repeatability ± 10 µm (± 1 µm with optional encoder) |