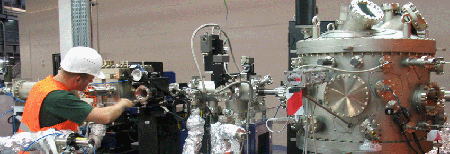

Mirror Chamber M2

Technical Description:

Beam switch into an existing beam line.

Installation Site: Bessy II

Technical Data:

| Frame: | Sand-filled, powder-coated welded structure made of structural steel | |

| Vertical cross table: | Travel across the incoming beam ±15mm (motorized) Travel along the incoming beam ±15mm (manual) |

|

| Lifting table: | Travel ±5mm (motorized) | |

| UHV vacuum chamber with built–in mirror bank: | UHV vacuum chamber with stationary baking facility. Mirror bank with cardanic mirror suspension. Motorized mirror adjustment with angular encoder for pitch movement (Rp=±1mrad; dRp=0.005mrad) Motorized mirror adjustment with angular encoder for roll movement (Rr=±7mrad; dRr=0.1mrad) Motorized mirror adjustment with angular encoder for yaw movement (Ry=±5mrad; dRy=0.25mrad) The mirror is indirectly water-cooled. Optical surface of the mirror: 20x100 mm A lifting unit lowers the mirror bank, if necessary. Thus the beam passes the mirror chamber without being influenced |

Customer & Period:

| Customer: |

Humboldt University Berlin (HUB) | |

| Period of Implementation: |

September 2003 to March 2004 |

JUX_PORTFOLIO_PRO_DATE

September 9, 2022

JUX_PORTFOLIO_PRO_CATEGORY

ROOT

JUX_PORTFOLIO_PRO_TAGS