Technical Description:

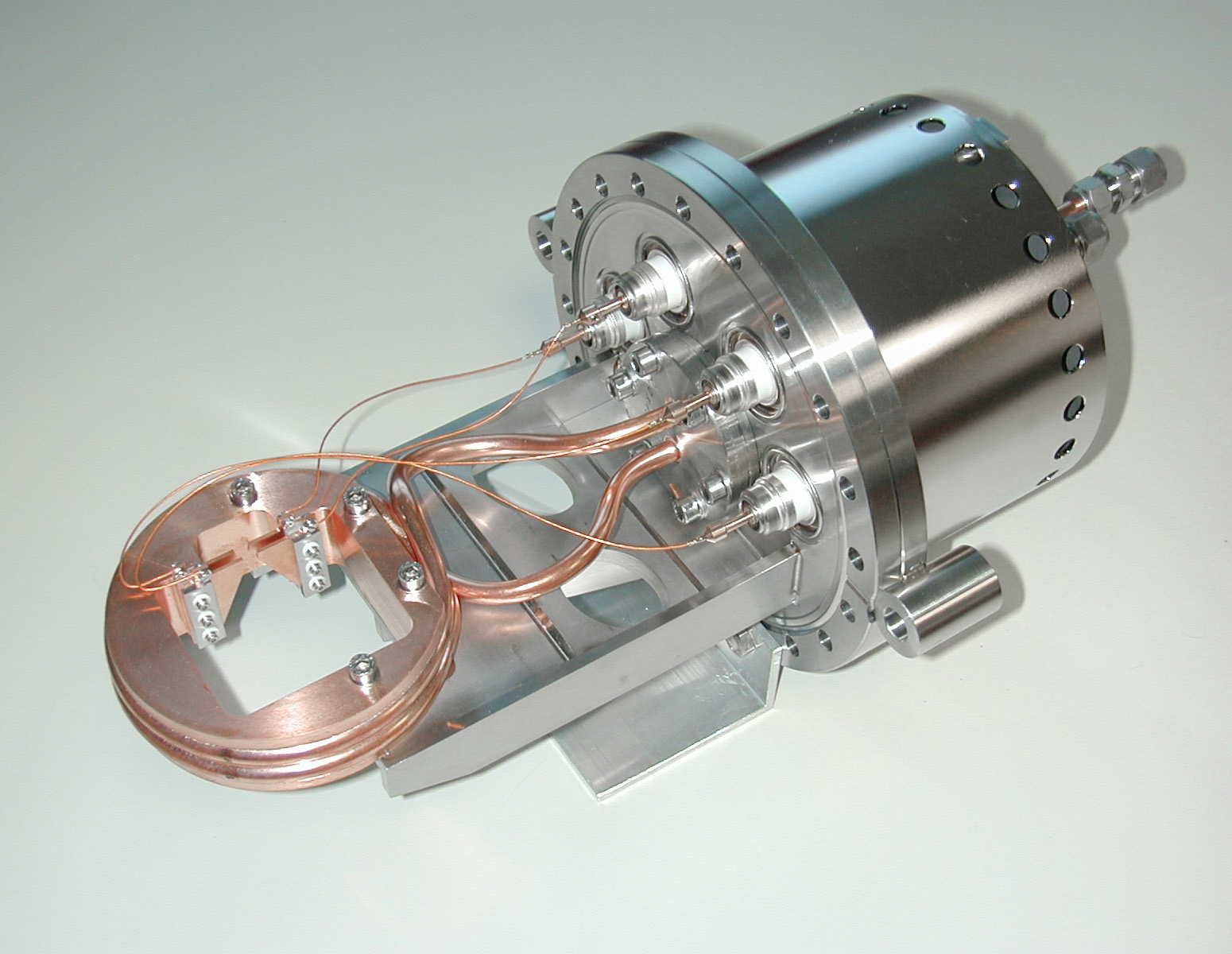

The beam position monitors are based on a development by Dr. Karsten Holldack, BESSY Berlin, in collaboration with FMB.

The beam position monitors use up to four blades, whose narrow fronts are oriented towards the radiation source, to scan the off-axis radiation of the dipole and determine on-line the position of the centre of the dipole radiation from the emitted signals.

The size and the geometry of the blades will be adapted to the beam characteristics at the place of the position monitor in order to achieve a maximum photocurrent yield at a maximum sensibility.

The blades for dipole applications consist of OFHC copper or Tungsten and will be actively cooled via heat conducting ceramics to resist the thermal load of the dipole radiation.

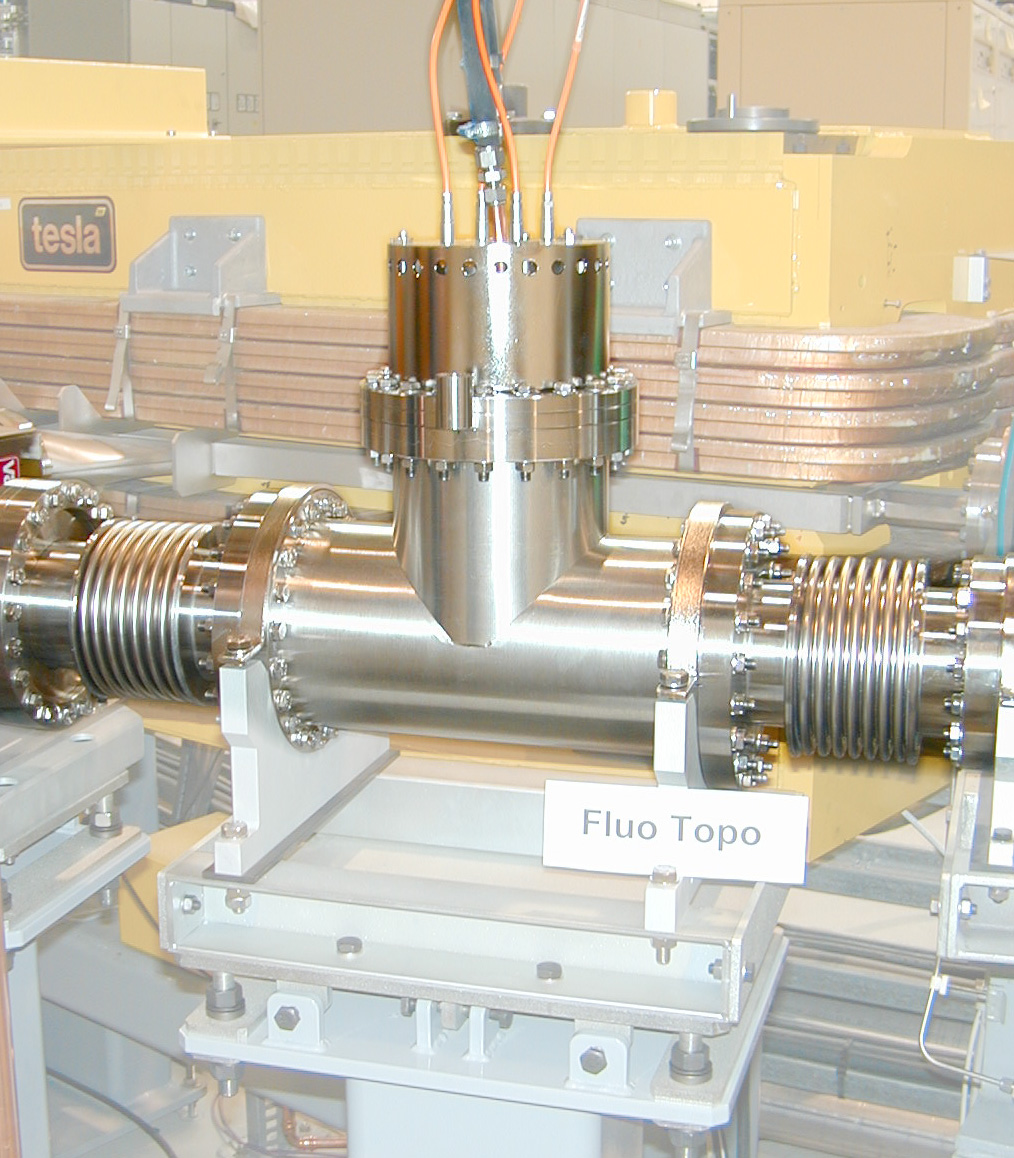

The beam position monitors are only for vertical diagnostic with the help of 2 staggered blade pairs.

Technical Data:

| Detector head: | OFHC-Copper (water-cooled) | |

| Blades: | Copper; thickness 1.5mm to 3.5mm (in reference to the distance between Monitor and source point) (Wiggler-BPM optional 0.2mm Tungsten / Molybdenum). Optional with an additional Pinhole Array (opposite the blade pairs). |

|

| AlN insulators / ZrO washers: | 0.5 mm AlN / ZrO-collar sleeves | |

| Base flange / installation depth: | Preferable DN 150 CF / 167mm | |

| Stand: | Steel, sand filled, polystyrene-insulated (according to special request) |

|

| Vertical / horizontal stroke: | manual adjustment: ± 10mm (x-, y-, z- direction) | |

| Electronics: | 4 channel-current to DC converter LoCuM-4 (100pA…1mA), internal BIAS supply (300V DC) |

|

| As options available: | Vacuum chamber with bellows (hydro formed or welded Bellows) The additional consideration of the precision stage is also possible: ±5mm (x-, z- direction) |

|

| UHV compatibility: | yes |