Technical Description:

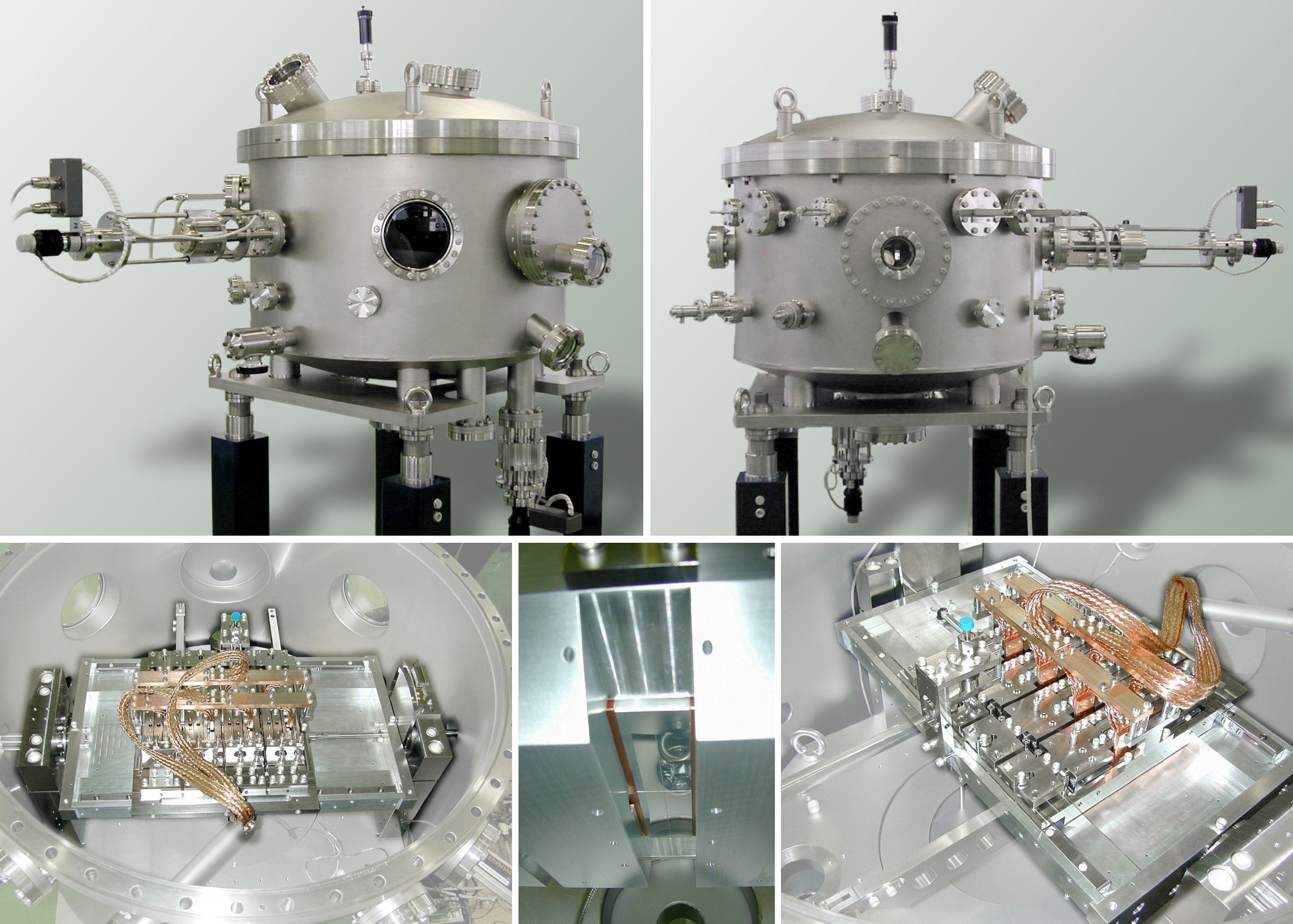

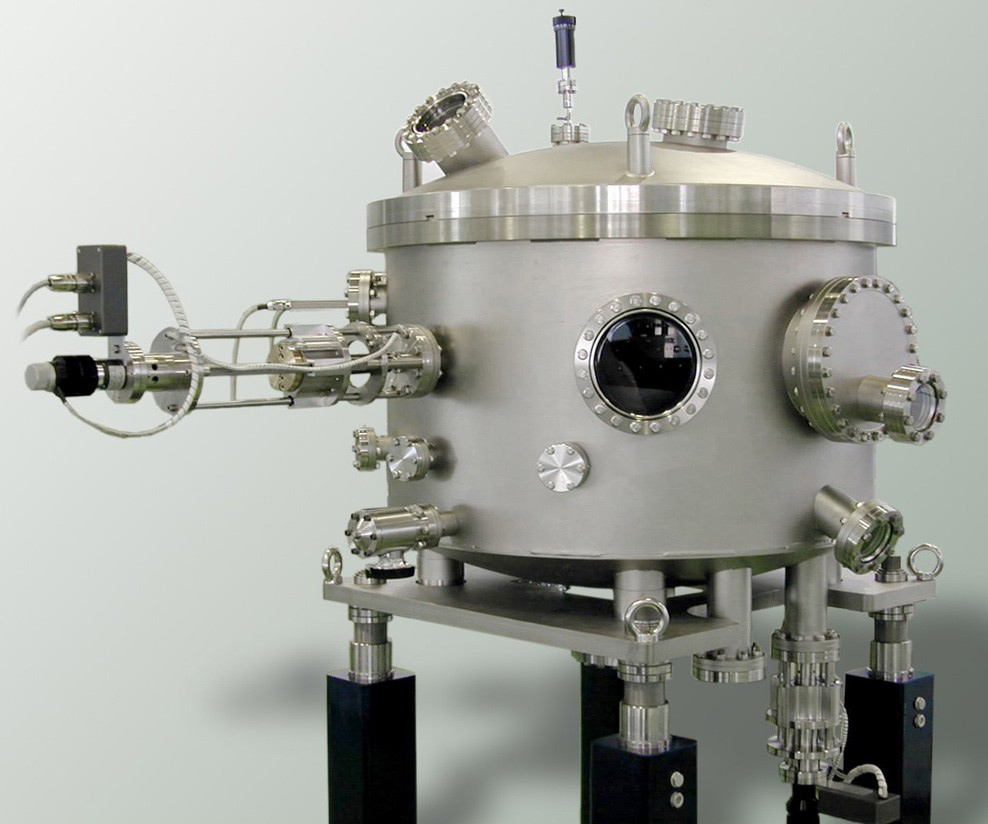

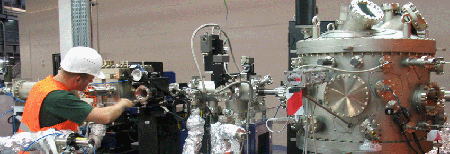

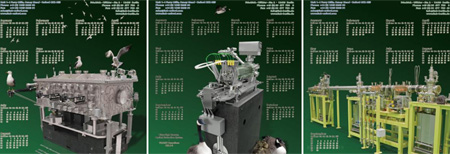

It is the task of the monochromator to realise the pitch movement of four gratings and to guarantee the exchange of the gratings.

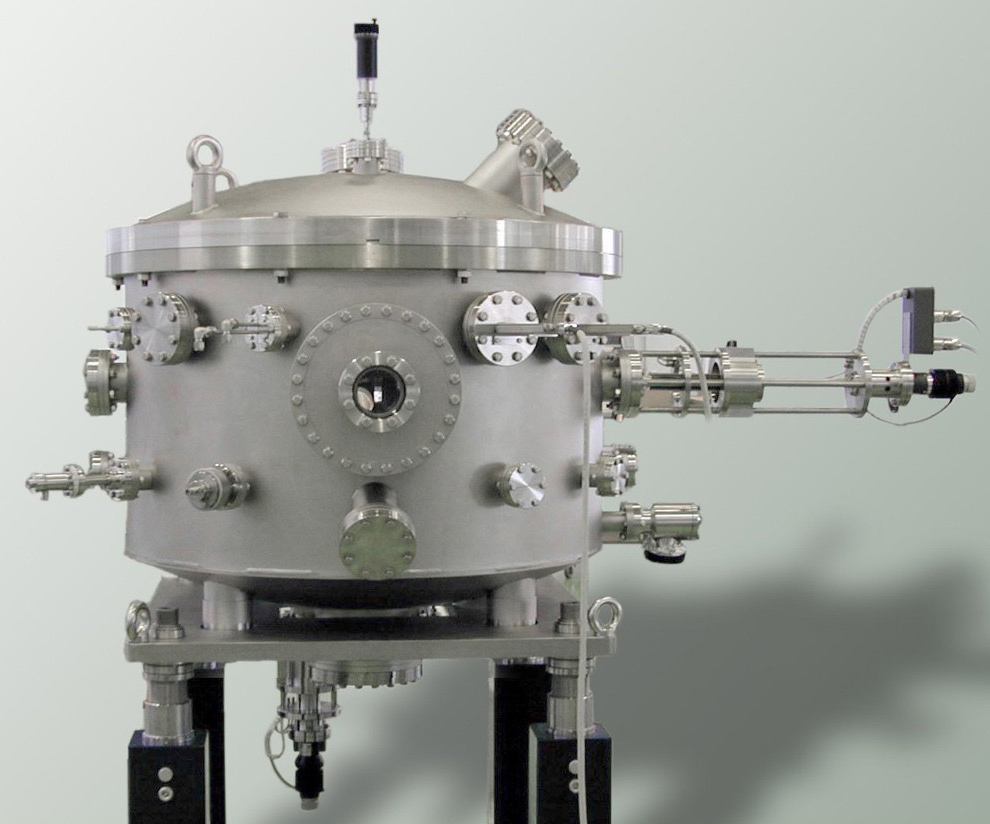

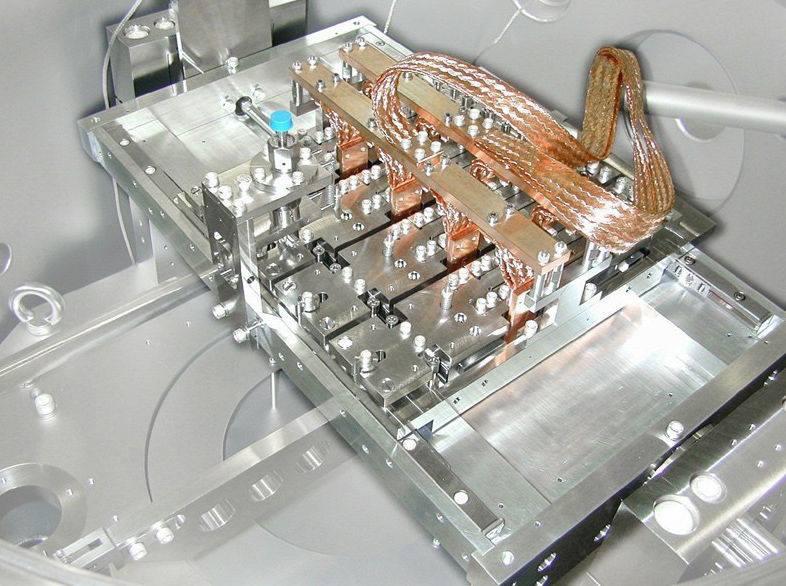

The gratings are arranged separately in highly precise and stable supports which are equipped with fine adjustment systems under vacuum.

The silicon gratings are downwardly oriented and can perform a pitch rotation of approx. 20°. The exact positioning of the grating surface in the pitch axis is important.

High–precision hybrid ball bearings will be used as bearing mechanism.

For the exchange of the gratings the gratings will travel in a linear slide. An optional pressure mechanism forces the respective active grating against a reference plate, so that a high repeatability of the grating position is achieved.

The pitching movement of the grating system is performed via a translatory movement which is transfered from the outside into the vacuum chamber via a membrane bellow.

The motorization is outside the vacuum, the stepping motors can be combined with harmonic drive gears which will allow very high transmission ratios and thus the necessary angular resolution for the pitching movement.

The exchange of the gratings will be performed via a translatory motion from the outside.

The pitch and exchanging positions of the gratings are read via linear and angular encoders, which can be operated in vacuum.

The entire grating mechanism is arranged on a very stable base plate which come from the outer main frame.

The monochromator frame consists of solid tubes which are welded to the floor base plate.

A sputtering ion pump (500 l/s) is used as a vacuum pump. The vacuum chamber has a diameter of approx. 800 mm and is completely metal–sealed. All four gratings are fitted with lateral cooling plates. Cooling is performed using water.

Technical Data:

| Gratings | ||

| Number : | 4 | |

| Bulk material : | Silicon | |

| Bulk dimension : | 180 x 38 x 35 | |

| Shape : | Spherical / Plane | |

| Grating fine adjustment : | Pitch, Roll, Yaw, Height possible under vacuum | |

| Grating cooling : | Water | |

| Grating pitch drive | ||

| Stepper motor : | 500 steps | |

| Gear : | Harmonic Drive | |

| Gear ratio : | 100 : 1 | |

| Vertical range : | + 25 … -45 mm relative to the horizontal position | |

| Vertical movement : | 0.00001 mm per full step | |

| Encoder : | incremental | |

| Encoder resolution : | 50 nm | |

| End switch number: | 2 x 2 (active and redundant) | |

| Grating change drive | ||

| Stepper motor : | 500 steps | |

| Gear : | Planetary Gear | |

| Gear ratio : | 6 : 1 | |

| Horizontal range : | 0 … 225 mm | |

| Horizontal movement : | 0.00033 mm per full step | |

| Encoder : | incremental | |

| Encoder resolution : | 1µm | |

| End switch number: | 2 x 2 (active and redundant) |

Customer & Period:

| Customer: |

Singapore Synchrotron Light Source (SSLS) | |

| Period of Implementation: |

September 2001 to May 2002 |