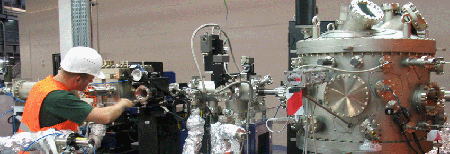

Technical Description:

3 pieces of water cooled Double–Crystal–Monochromator with 2 crystal pairs.

The function of the Double Crystal Monochromator (DCM) is to select and transmit X–ray radiation of the desired photon energy from an incident white synchrotron radiation beam.

The DCM will be incorporated into a beamline with a horizontal incident beam. It will use two parallel crystal pairs in (+, –) configuration to produce a monochromatic exit beam which is running parallel to the incident white X–ray beam.

When Si (111) crystals are used the energy of the monochromatic beam will be continuously selectable from 3 keV to 20 keV.

The energy will be selected by rotating both crystals (varying the Bragg angle) whilst keeping the crystals parallel to each another.

The beam offset, i.e. the distance between the optical axes of the incident beam and the exit beam, does not change during the energy scan. This is realised by a common rotation of both crystals and two perpendicular motions of the second crystal.

The DCM is designed for a beam offset between 40mm and 46 mm. Different beam offsets are available on request.

The Bragg angle can be set between –3° and 50°. In the 0° position (horizontal crystal orientation) the first crystal can be moved out of the Bragg rotation axis to let the beam go through.

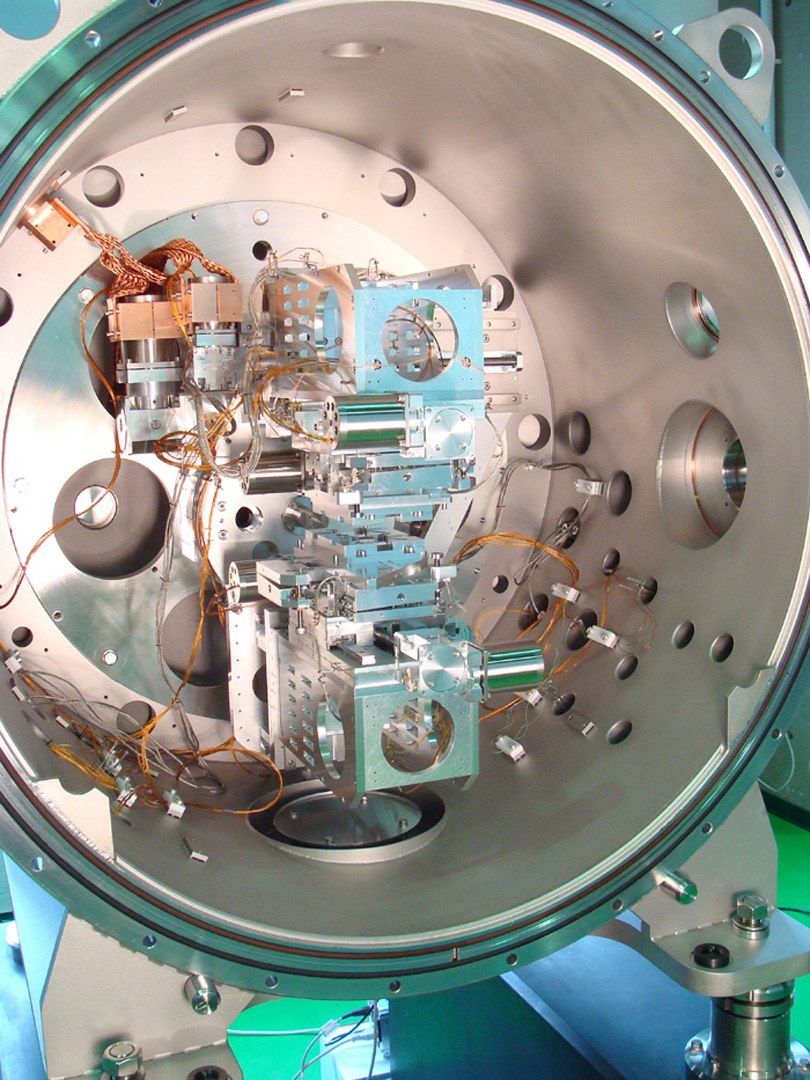

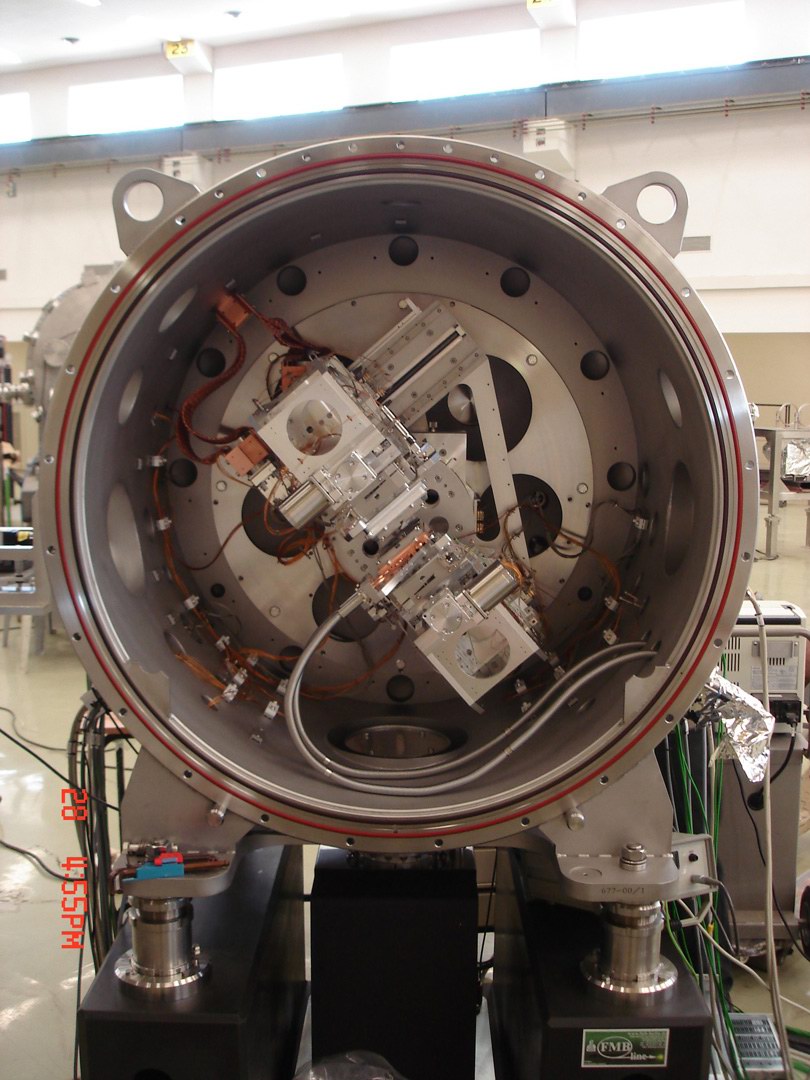

All positioning elements are in vacuum drives. These are:

• Bragg angle goniometer (stepper driven)

• 1 Linear slide (stepper driven) for crystal 1 positioning

• 2 Linear slides (stepper driven) for crystal 2 positioning

• 2 Linear slides (stepper driven) for crystal change

• 4 angular drives (manual/picomotor driven) fine positioning of the crystals in roll and pitch

• 1 angular drive piezo driven for fast feedback control of crystal 2 pitch

The DCM is high–vacuum compatible.

The first crystal is indirectly water–cooled in order to dissipate the absorbed photon energy.

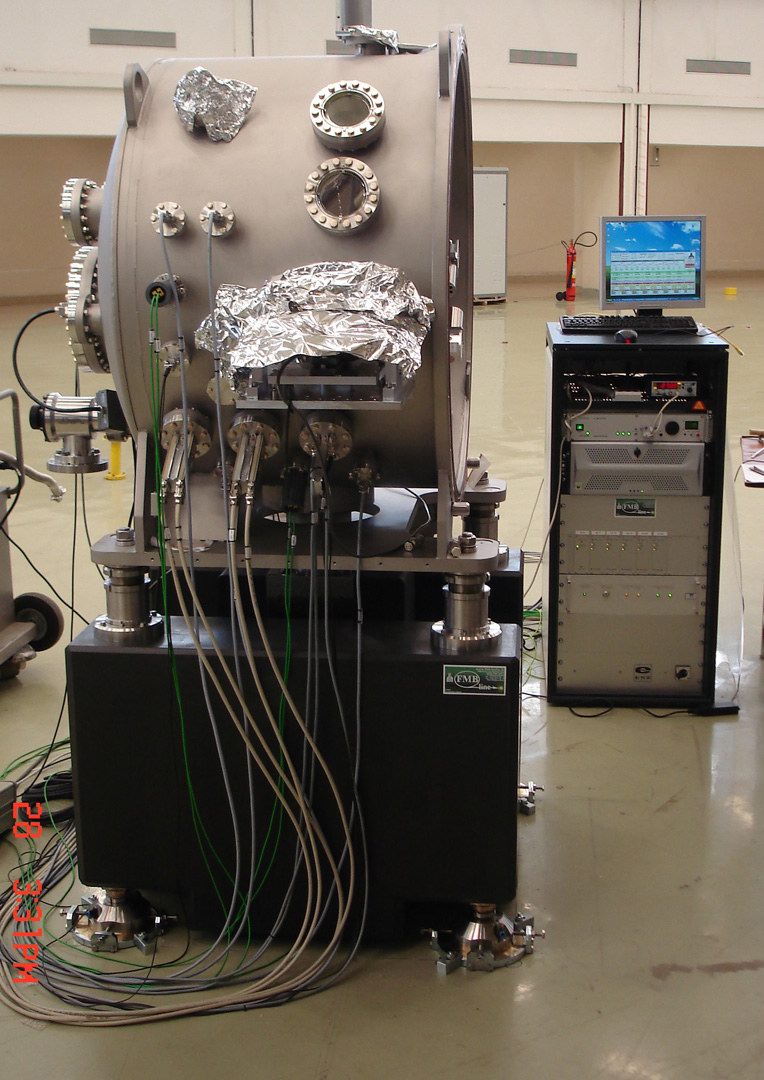

The DCM control system is mounted in a single 19”–24U control rack. It includes a control PC running on Microsoft Windows XP.

The control software based on AgilentVEE provides a graphical user interface.

Technical Data:

| Bragg angle range: | -3° .. 50° | |

| Bragg angle resolution: | 0.1 arcsec | |

| Crystal 1 size: (length x width x thickness) |

(100 x 60 x 10)mm³ | |

| Optical surface crystal 1: (length x width) |

(100 x 50)mm³ | |

| Crystal 2 size: (length x width x thickness) |

(116 x 60 x 10)mm³ |

|

| Optical surface crystal 2: (length x width) |

(116 x 50)mm³ | |

| Size (flange to flange): (length x width x height) |

(1150 x ca. 1400 x 2075)mm³ | |

| Weight: | approx. 2000 kg |

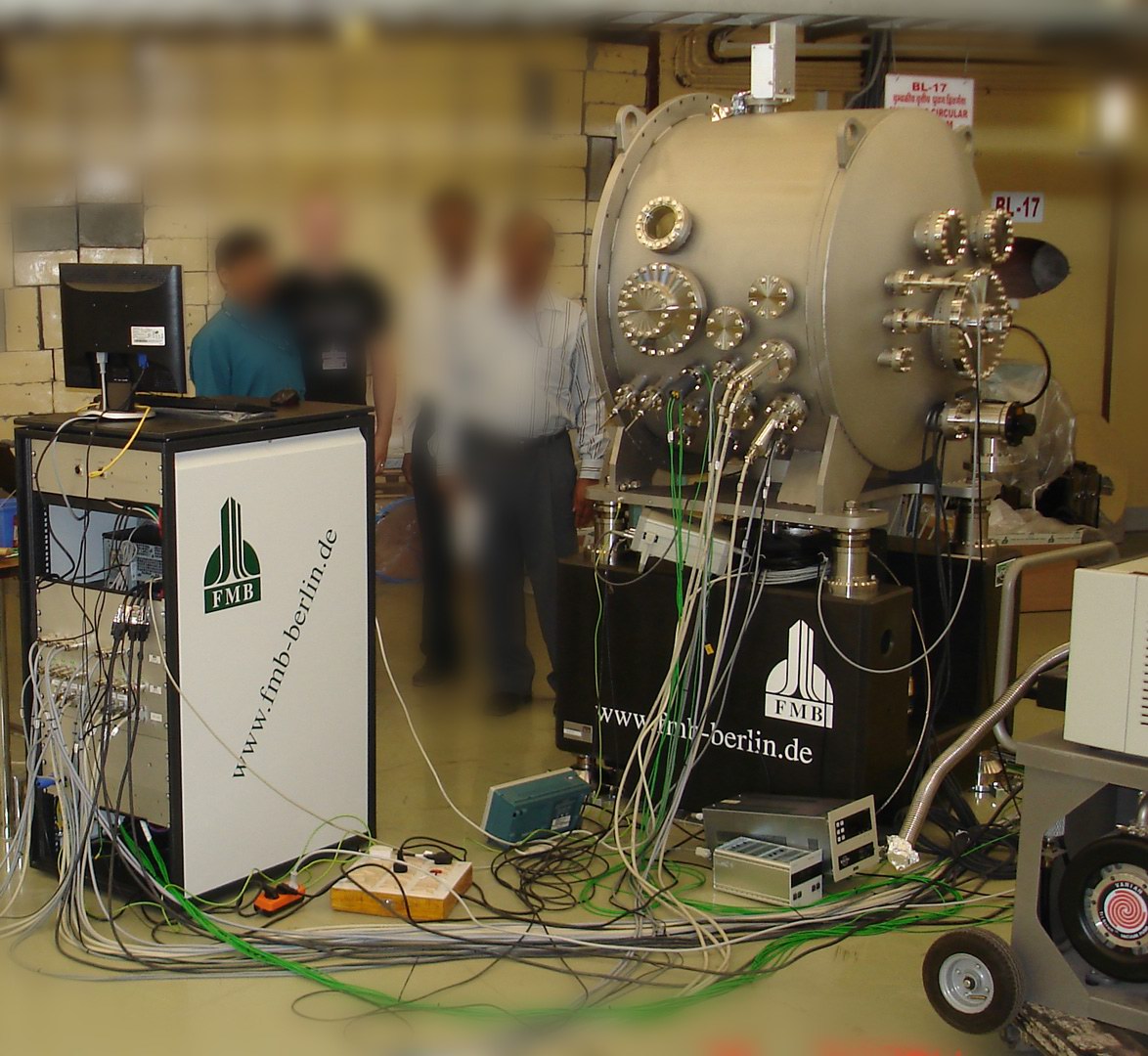

Customer & Period:

| Customer: |

RRCAT Indore, India ; BARC Mumbai, India | |

| Period of Implementation: |

February 2007 to September 2008 |