Technische Beschreibung:

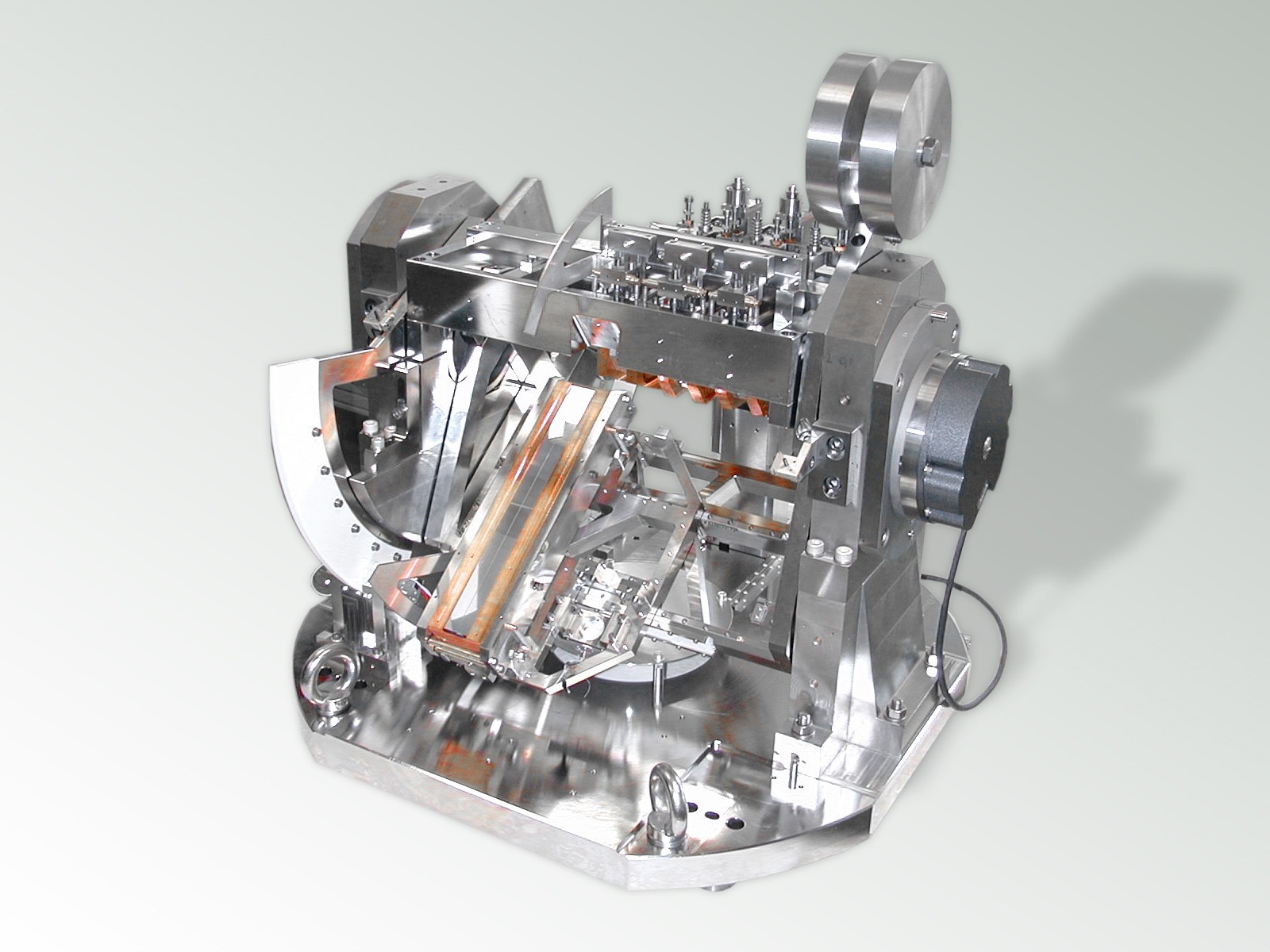

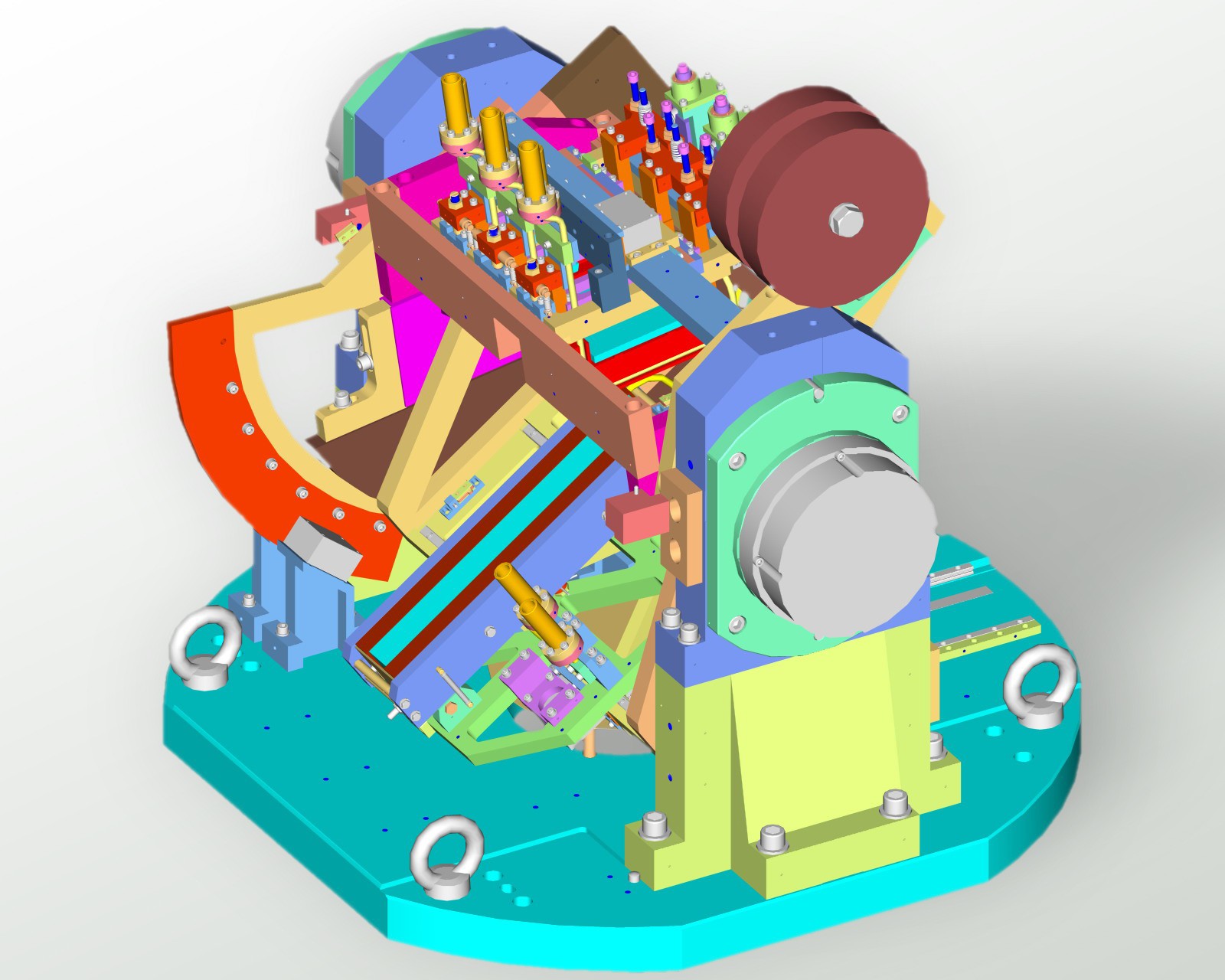

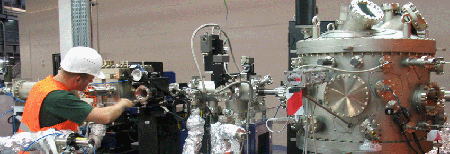

It is the task of the monochromator to realize the necessary pitch movement of the gratings and of the mirror as well as to guarantee the exchange of the gratings and of the mirror.

The gratings and the mirrors are arranged separately in highly precise and stable supports which are equipped with fine adjustment facilities.

A normal incidence mirror and a normal incidence grating are used for the lower energies. The gratings are oriented towards the bottom, while the mirror surface shows upwards.

The gratings can execute a pitch rotation up to 55°, the mirror has an angle range of 35°. The exact positioning of the grating surfaces in the rotational axis is important. High–precision hybrid ball bearings will be used as bearing mechanisms.

For the exchange the gratings and the mirror travel in separate linear slides. The exchanging positions are read via linear encoders, which can be operated in the vacuum. The pitch positions are determined using high–precision angular encoders, which are mounted directly on the axes in the vacuum.

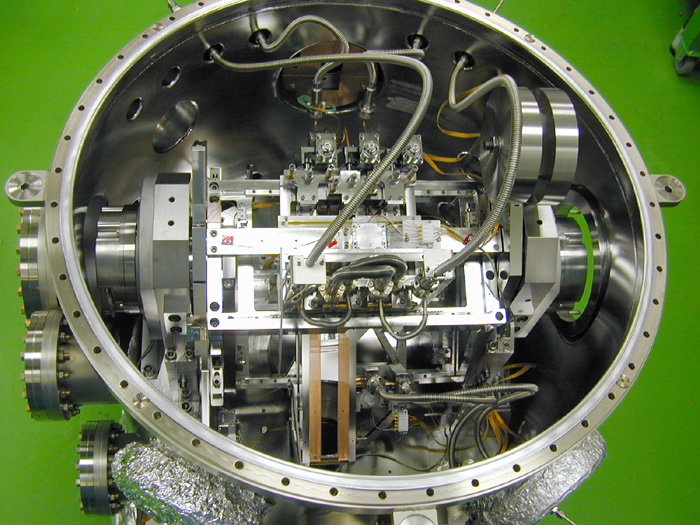

The entire mirror and grating mechanism is based on a very stable base plate which is screwed to feet which come from the outer main frame and are led through the chamber wall. Thus the mechanism is not connected with the chamber and is isolated from thermal and mechanic deformations of the chamber. The monochromator frame consists of solid pipes or a monolithic block and allows an adjustment in all six degrees of freedom. A sputtering ion pump is used as a vacuum pump.

The vacuum chamber has a diameter of approx. 800 mm and is completely metal–sealed. All optical elements are fitted with lateral cooling plates. Cooling is performed using water.

Technische Daten:

| Energy range: | 3eV … 1500eV | |

| Mx. Resolution E/ÄE: | Up to 100000 | |

| Modes: | Normal incidence and grazing incidence | |

| Pitch angle of the gratings: | -2° … 55° | |

| Max. number of gratings: | 4 | |

| Max. grating size: (length x width) |

120 x 40 mm2 | |

| grating cooling: | Water | |

| Mirror size: (length x width) |

300 x 50 mm2 | |

| Mirror cooling: | Water | |

| Grating and mirror pitch drive: | In vacuum piezo motors or Stepper motors with gears on air | |

| Grating and mirror change drive: | In vacuum piezo motors or Stepper motors with gears on air | |

| Angular encoder: | Heidenhain UHV type | |

| Linear encoder: | Renishaw UHV type | |

| Base pressure: | < 5 x 10-10 mbar |

Kunde & Zeitraum:

| Kunde: |

BESSY, Berlin, Germany | |

| Realisierungszeitraum: |

2004 bis Dezember 2005 |