Technical Description:

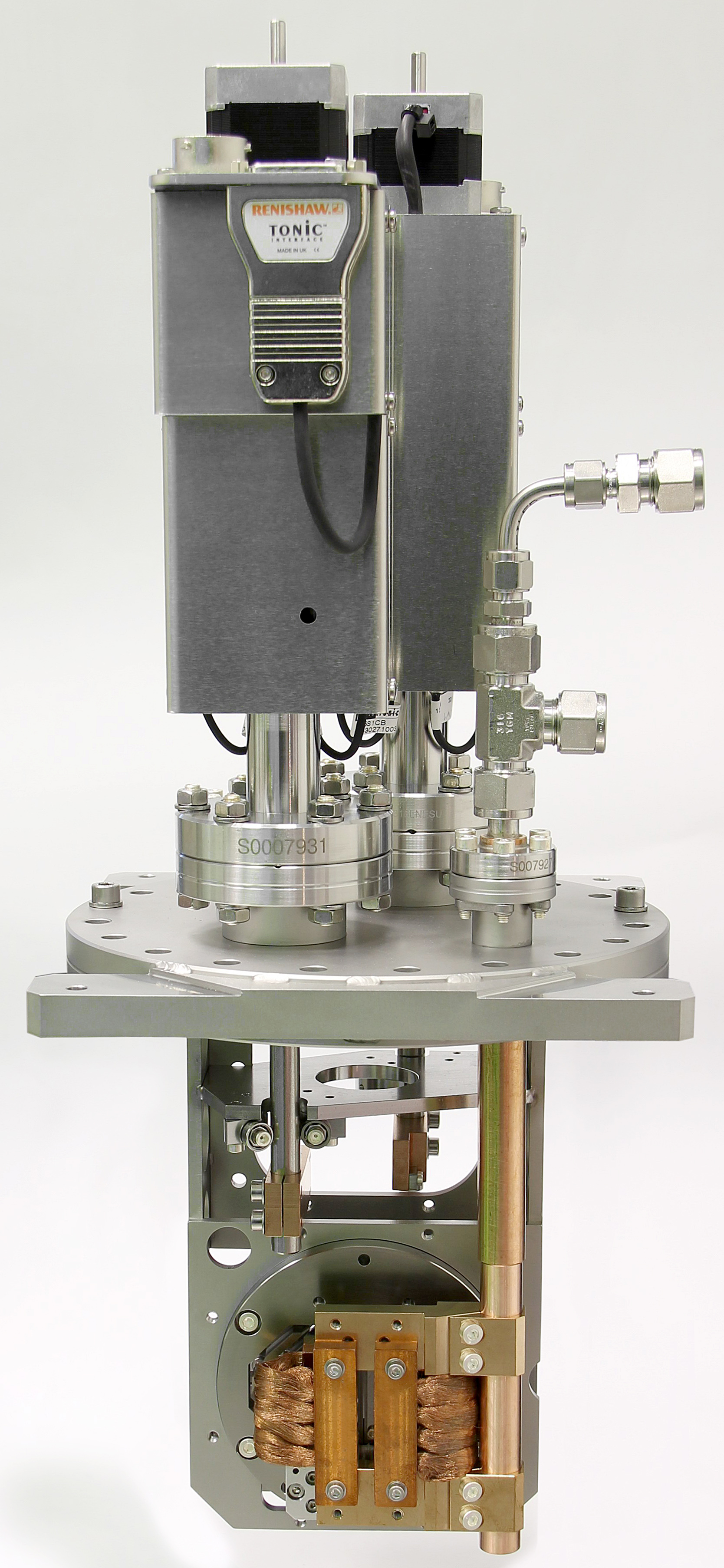

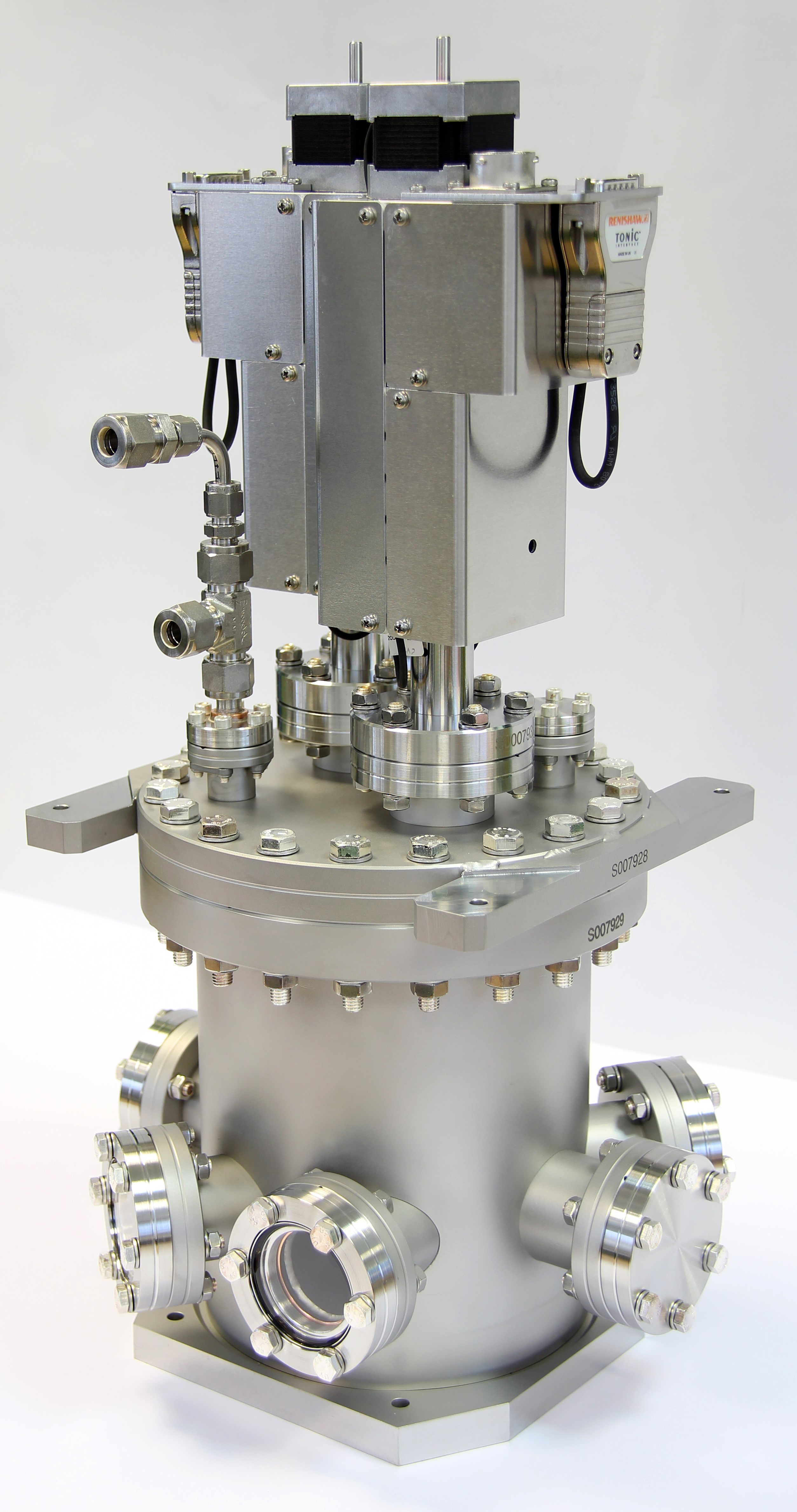

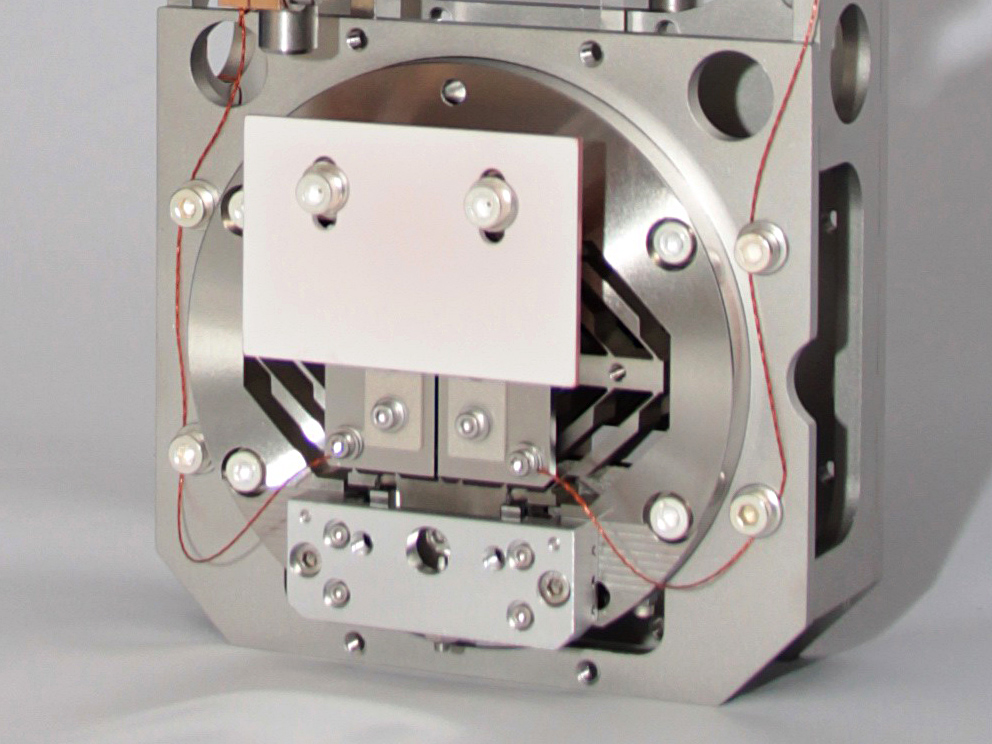

The FMB precision slit is a precisely controllable aperture. Two highly precise blades are being moved parallel and symmetrically by a backlash-free flexure mechanism. The gap size is usually defined in vertical direction only but systems with a second blade pair defining an additional aperture in horizontal direction are also available.

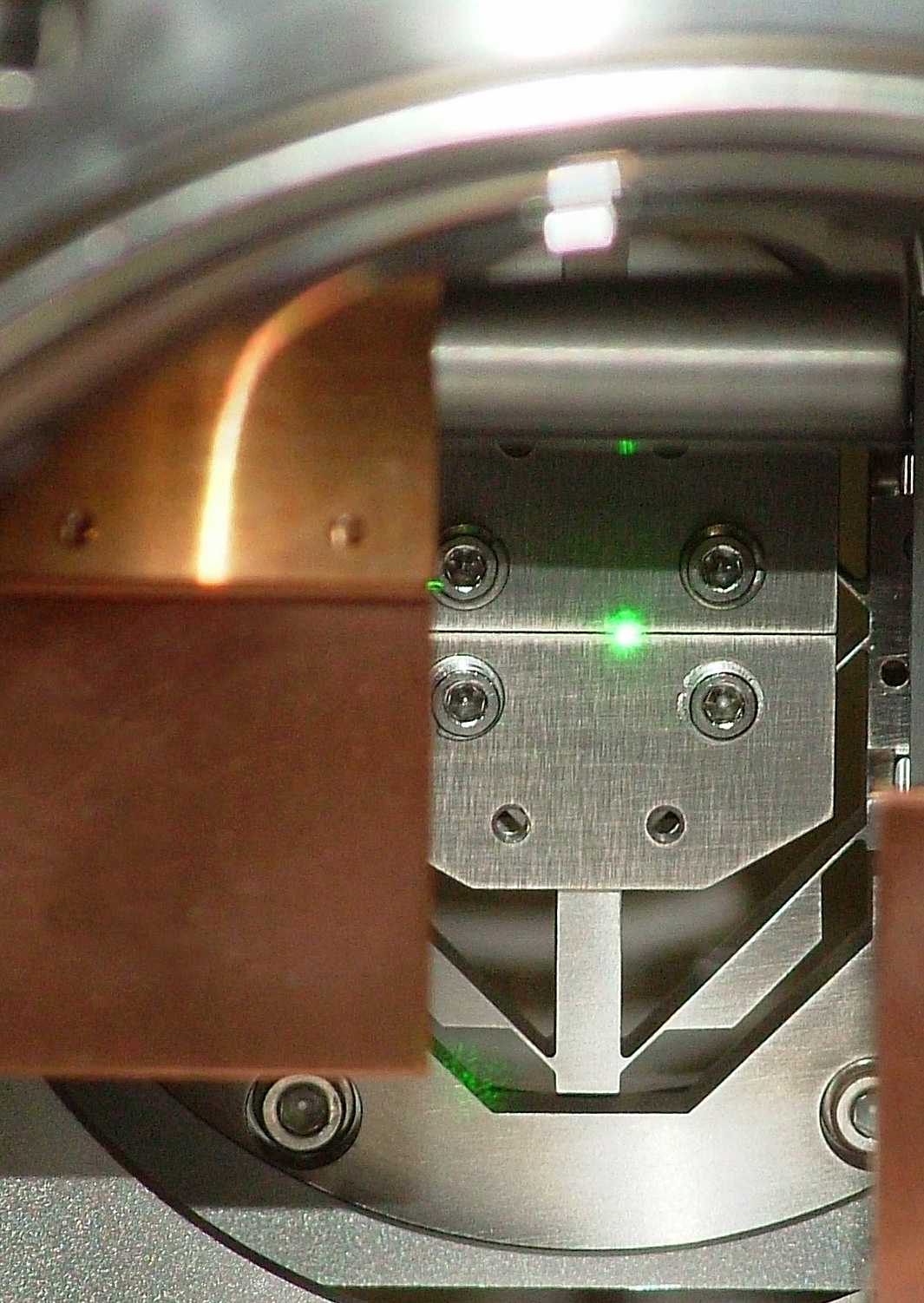

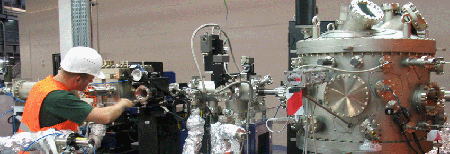

The precision slit assembly is based on a DN150CF flange and can be mounted on top of any sufficient vacuum chamber. Using diagonal viewports in the vacuum chamber, it is possible to observe the opening of the slit gap. A viewport orientated orthogonally to the incoming allows a grazing incidence view to the blade edge, useful for surveying of the longitudinal slit position.

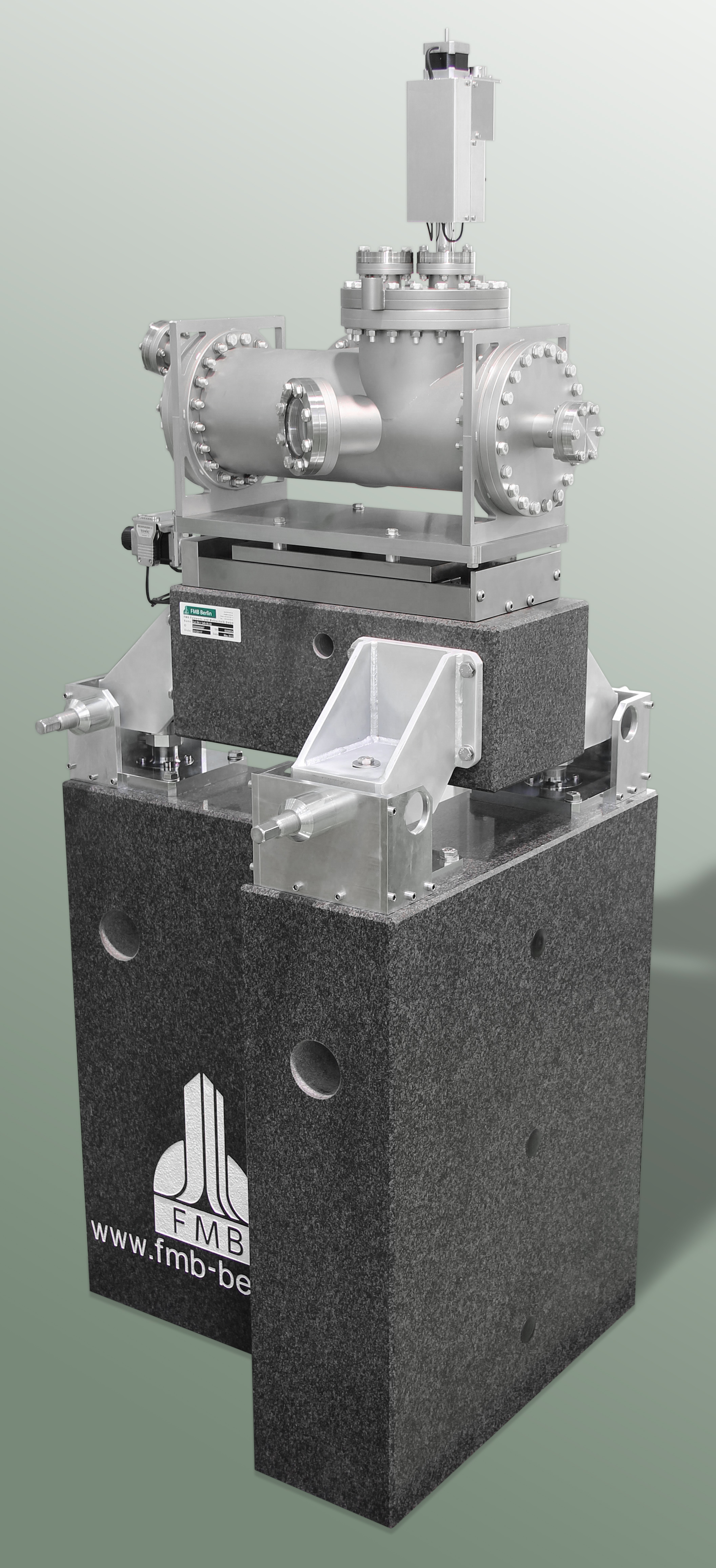

Different support designs are available on request. Granite or concrete based supports are typically used.

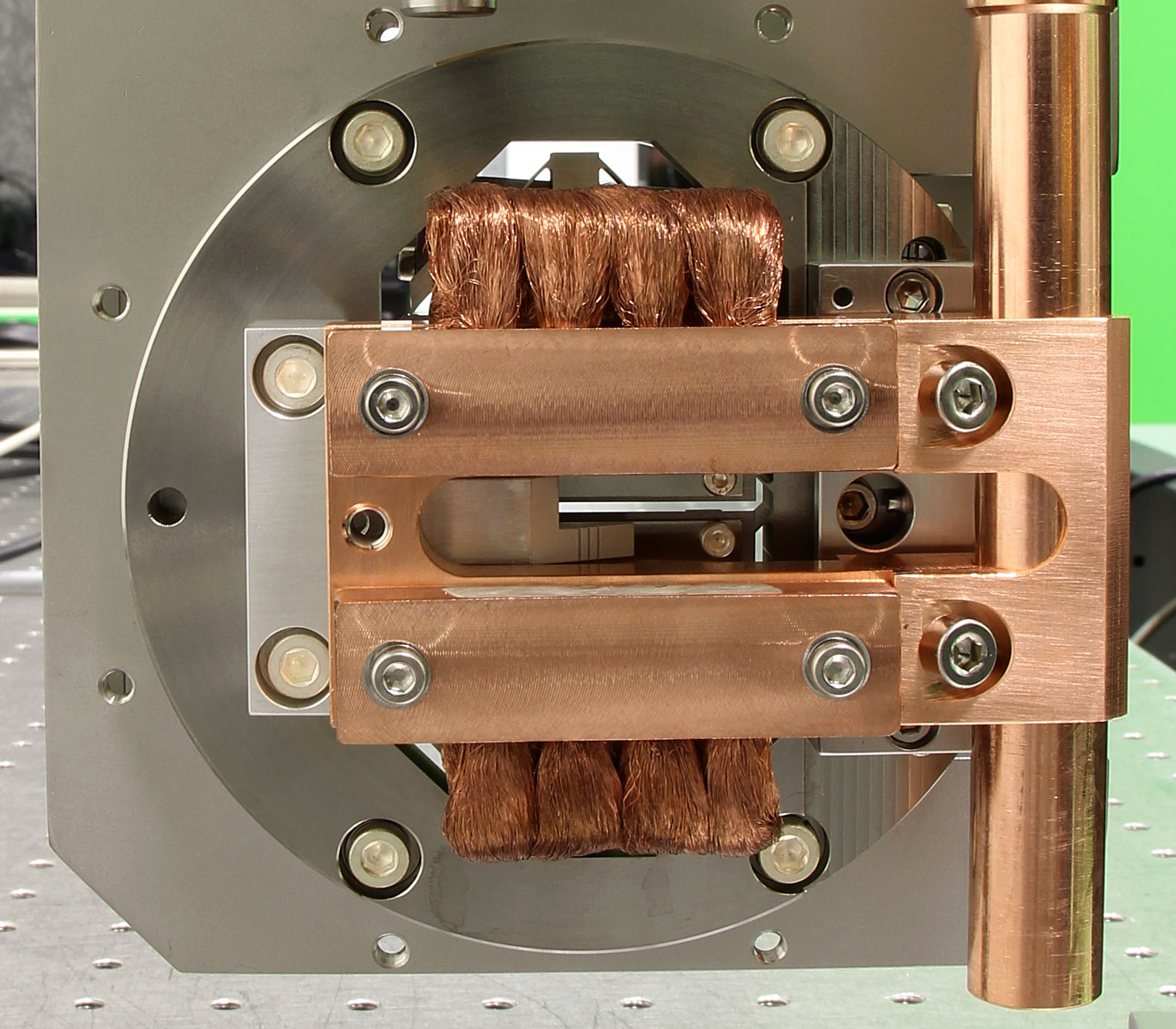

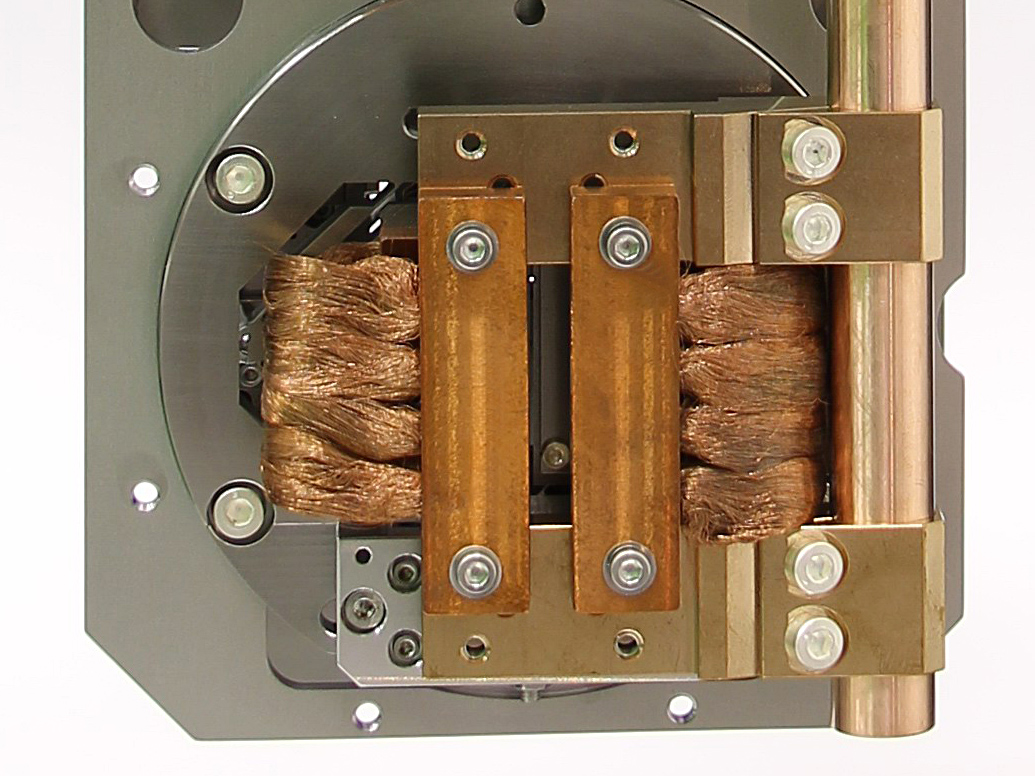

The slit blades can be either electrically isolated or temperature stabilized. In the latter case, the blades are connected via Copper braids to the water cooling. When electrically isolated, the photo current of each blade can be measured individually.

A fluorescence screen can be mounted at the upstream side of the slit blades just below the bottom blade edge or above the upper blade edge. It allows a fluorescence image by keeping the beam path through the precision slit unobstructed.

Technical Data:

| Blade material | Tungsten or Tungsten-Carbide (other materials on request) | |

| Blade edge length | 38 mm | |

| Blade thickness | 2.5 mm | |

| Thickness at blade edge | ≤ 0.1 mm | |

| Blade rear side rake angle | 10° or 20° (other angles available on request) | |

| Edge straightness & roughness | ≤ 1 µm | |

| Slit gap parallelism | ≤ 1 µm over 20 mm edge length | |

| Minimum slit gap | 0 mm (closed slit) | |

| Maximum slit gap | 2.5 mm (symmetrically opened) | |

| Drive | Stepper motor | |

| Fullstep resolution | 0.05 µm (gap size) / full step | |

| Encoder resolution Incremental encoder Absolute encoder | 0.05 µm (gap size) / count 0.05 nm (gap size) / count | |

| Repeatability | ≤ 1 µm | |

| Limit switches | 2 limit switches per limit, normally closed | |

| Vacuum compatibility | UHV (10-10 mbar) | |

| Baking temperature | 200°C for all vacuum sided parts 100°C for all air sided parts incl. precision feedthrough |

|

| Options, available on request: |

|